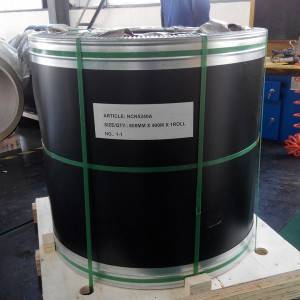

Rubber Coated Metal UNX4035-F

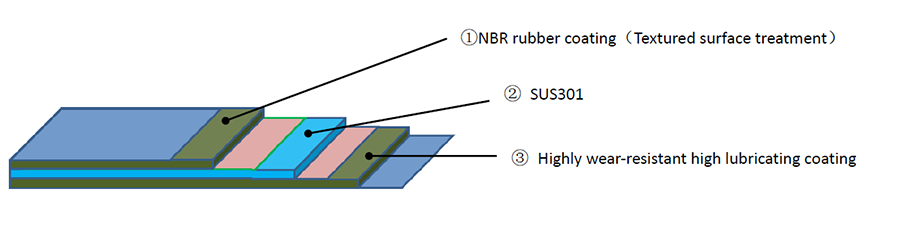

Construction

Specifications

| Type |

Total thickness |

Rubber thickness |

The other side |

metal |

|

|

metal type |

thickness(mm) |

||||

| UNX4035-F |

0.40 |

0.025*single sides | PTFE | 301 |

0.35 |

| UNX5045-F |

0.50 |

0.025*single sides | PTFE | 301 |

0.45 |

| UNX6055-F |

0.60 |

0.025*single sides | PTFE | 301 |

0.55 |

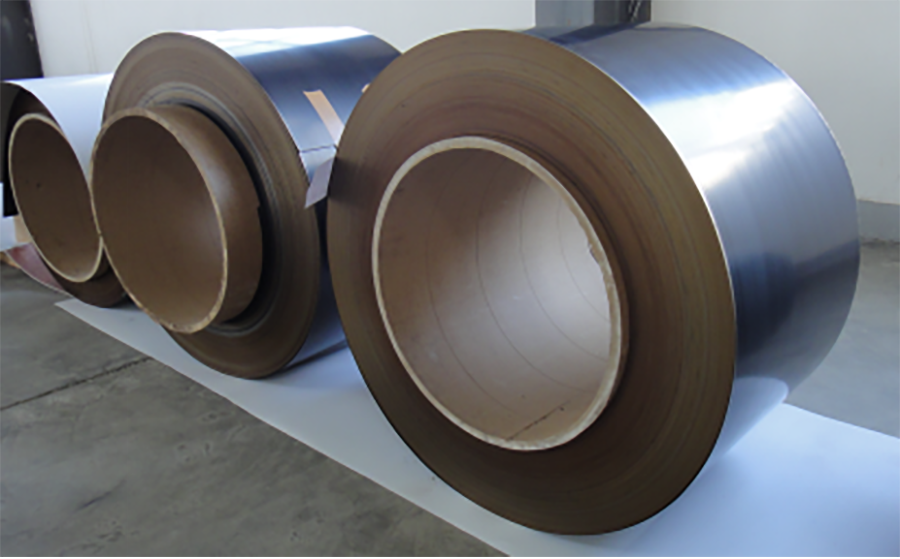

The First RCM Production Line in China

The production line is 360 meters long in total and 20 meters width, the key equipments are from France, Germany and Japan.

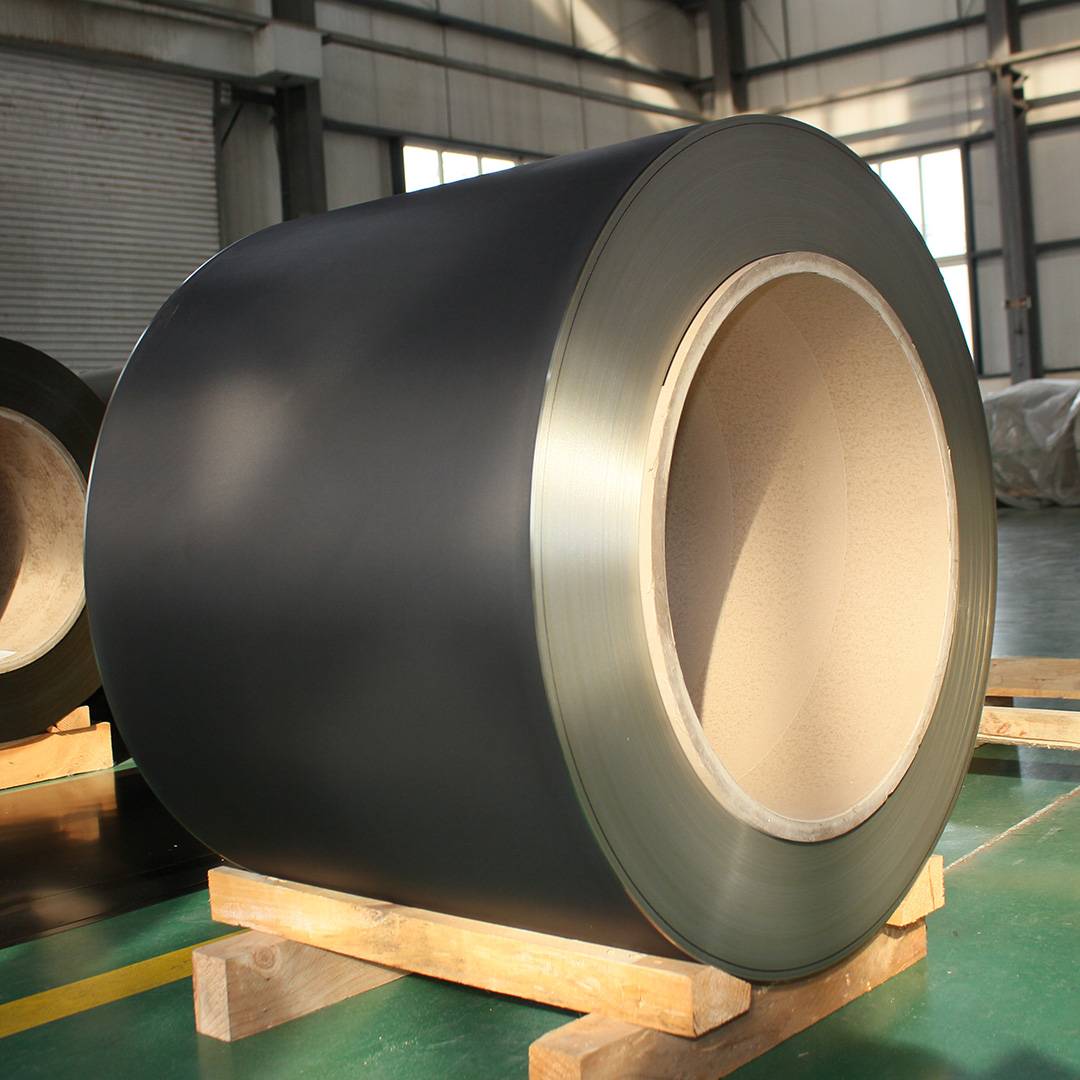

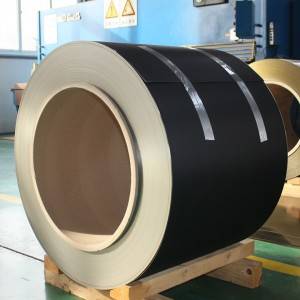

Product Dimension

Available metal substrates thickness are between 0.2mm-0.8mm.Max width is 800mm.Rubber coating thickness is between 0.02-0.12mm single and double-side rubber coated metal roll material can meet the requirement of different customers.

Main Application

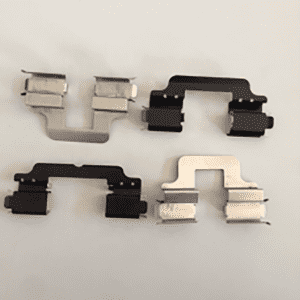

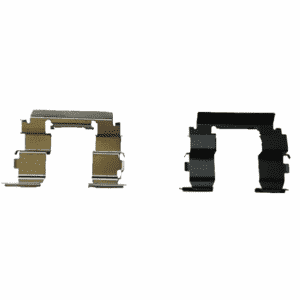

Mainly used as the noise damping and shock absorption shim for brake system. This material is especially suitable for the pads fixed by clip.

F series cloth rubber coated metal sheet for abutment clips is based on stainless steel, using advanced processing technology to coat the surface of the metal plate with cloth pattern rubber coating. It’s a composite material with high wear-resistant and highly lubricated rubber or Teflon coating.

Characteristics

- High adhesive force of the rubber coating and suitable for high temperature environment and fluids including engine oil, anti-freezer and coolant, etc.

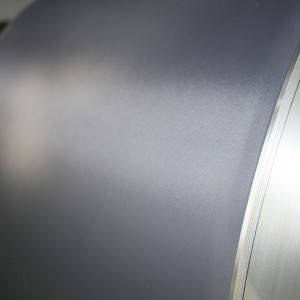

- Uniform thickness of steel plate and rubber coating and the surface is flat and smooth.

- Steel plate is with anti-rust treatment and bear good corrosion resistance property.

- Fine shock damping and noise absorption effect. High cost performance and can replace the import material.