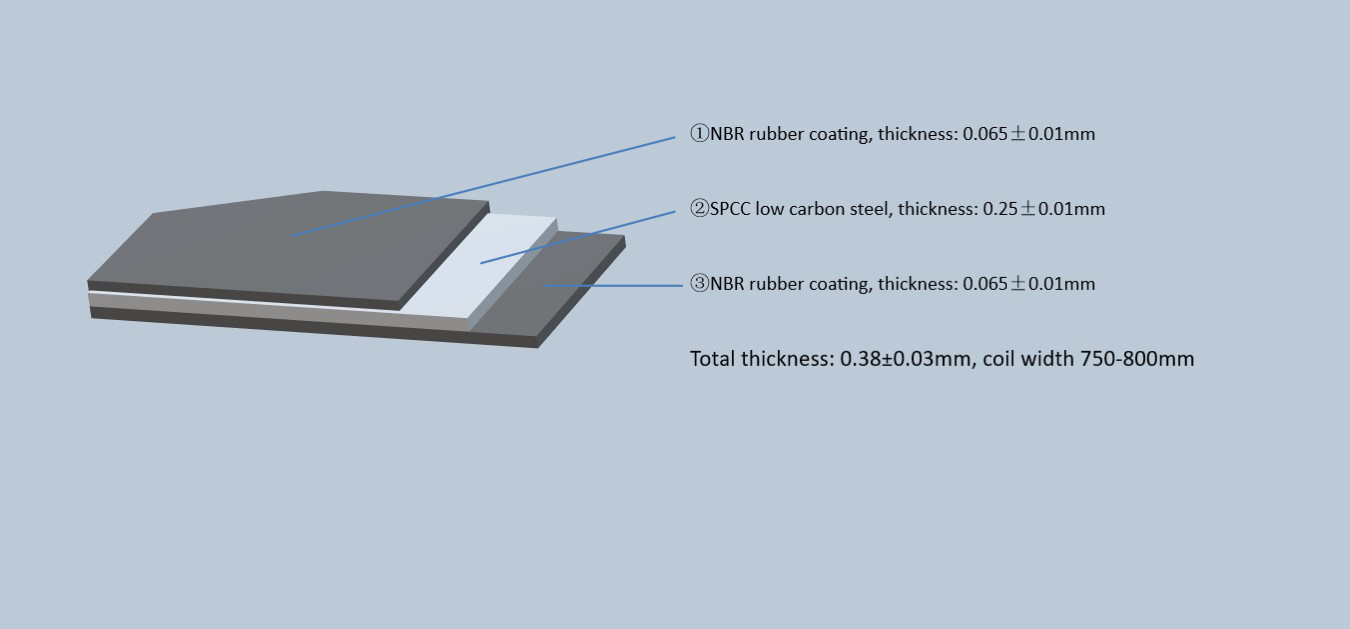

Rubber Coated Metal – SNM3825

Specifications

Excellent high and low temperature resistance; working temperature is between-30℃and 180℃.

Good seal ability and suitable for gas and fluid.

Good fluid resistance and suitable for various kinds of complicated environment, especially suitable for mechanical oil, antifreeze and coolant, etc.

Tensile strength can reach 100MPa.

Excellent compression, recovery and stress relaxation performance.

Good anti-ageing property.

Fine processing property and can be processed automatically in continuous way which keep the same lot gaskets in good consistence with high efficiency.

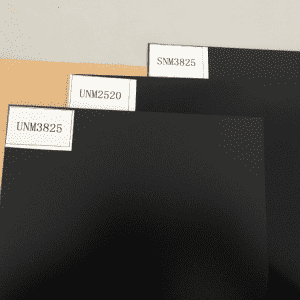

| Type | Total thickness | Rubber thickness | metal | |

| metal type | thickness(mm) | |||

| SNM3825 | 0.38 | 0.065* 2 sides | SPCC | 0.25 |

| SNM2520 | 0.25 | 0.025*2 sides | SPCC | 0.20 |

| SNM3020 | 0.30 | 0.05*2 sides | SPCC | 0.20 |

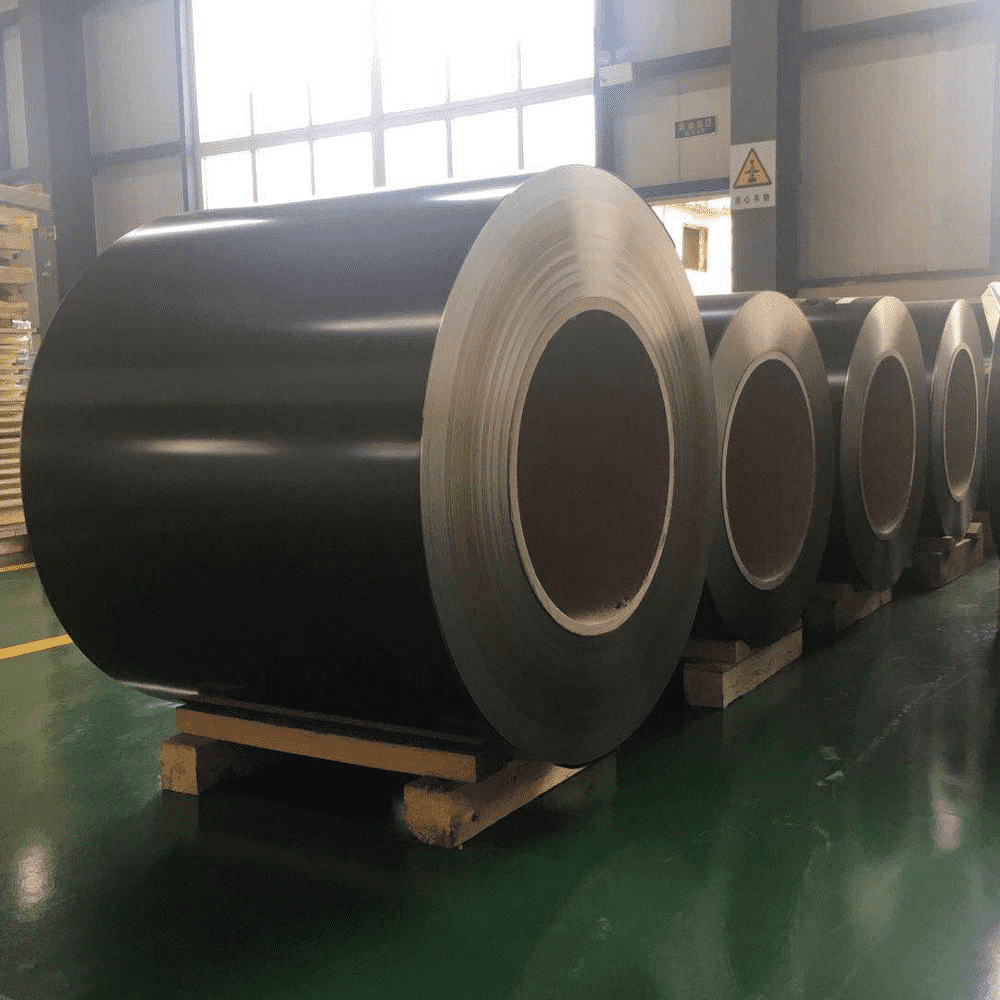

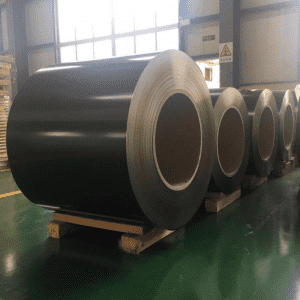

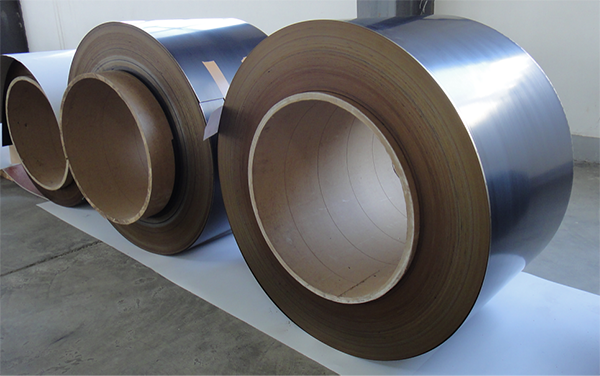

The First RCM Production Line in China

The production line is 360 meters long in total and 20 meters width, the key equipments are from France, Germany and Japan.

The First RCM Production Line in China

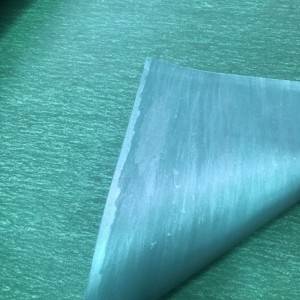

Available metal substrates thickness are between 0.2mm-0.8mm.Max width is 800mm.Rubber coating thickness is between 0.02-0.12mm single and double-side rubber coated metal roll material can meet the requirement of different customers.

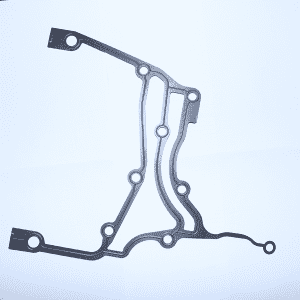

Main Application

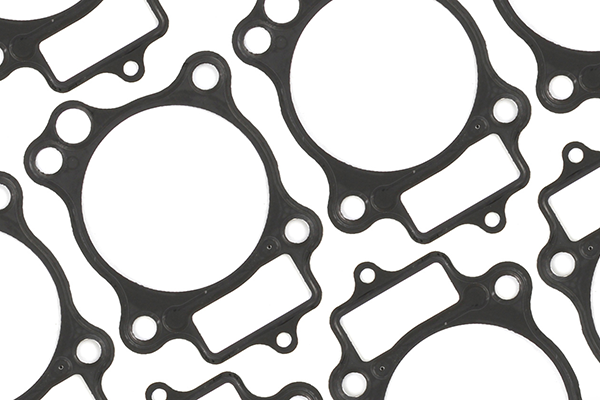

Rubber coated metal coil is a kind of composite sheet made of metal base material with various kind of rubber coating on both sides. Rubber coated metal sheet gives the consideration of both metal rigidity and rubber flexibility for its special construction.

So this material is suitable gasket material for automobile, motorcycle, refrigerator, compressor, etc. It has excellent performance in seal ability, compression and recovery, creep relaxation, fluid resistance and durability, coolant and low temperature resistance, etc.

Characteristics

*Excellent heat and low temperature resistance; working temperature between -30℃ and 180℃;

*Excellent mechanical performance; the tensile strength reaches 100MPa with excellent compression, recovery and stress relaxation;

*Good seal ability and suitable for gas and fluid;

*Good fluid resistance for various complicated environment and specially suitable for motor oil, solvent oil, coolant and antifreeze;

*Good anti-ageing property;

*Good machinability and can be processed automatically in continuous way which keep the same lot gaskets in good consistence in quality.