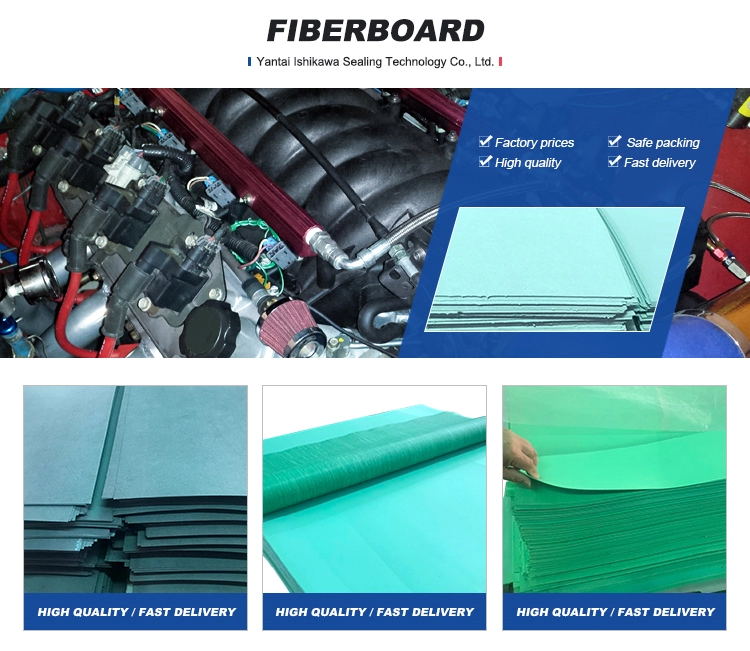

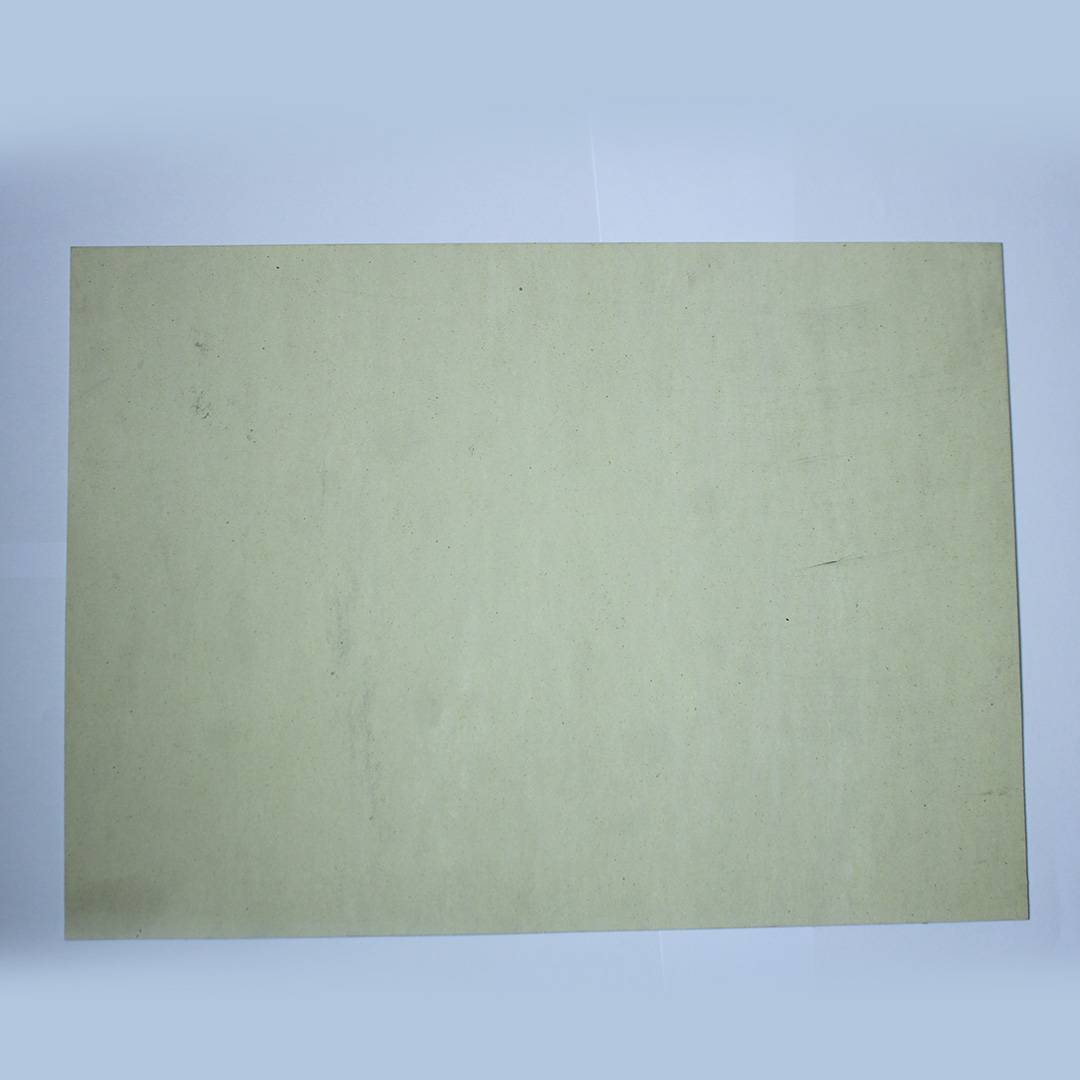

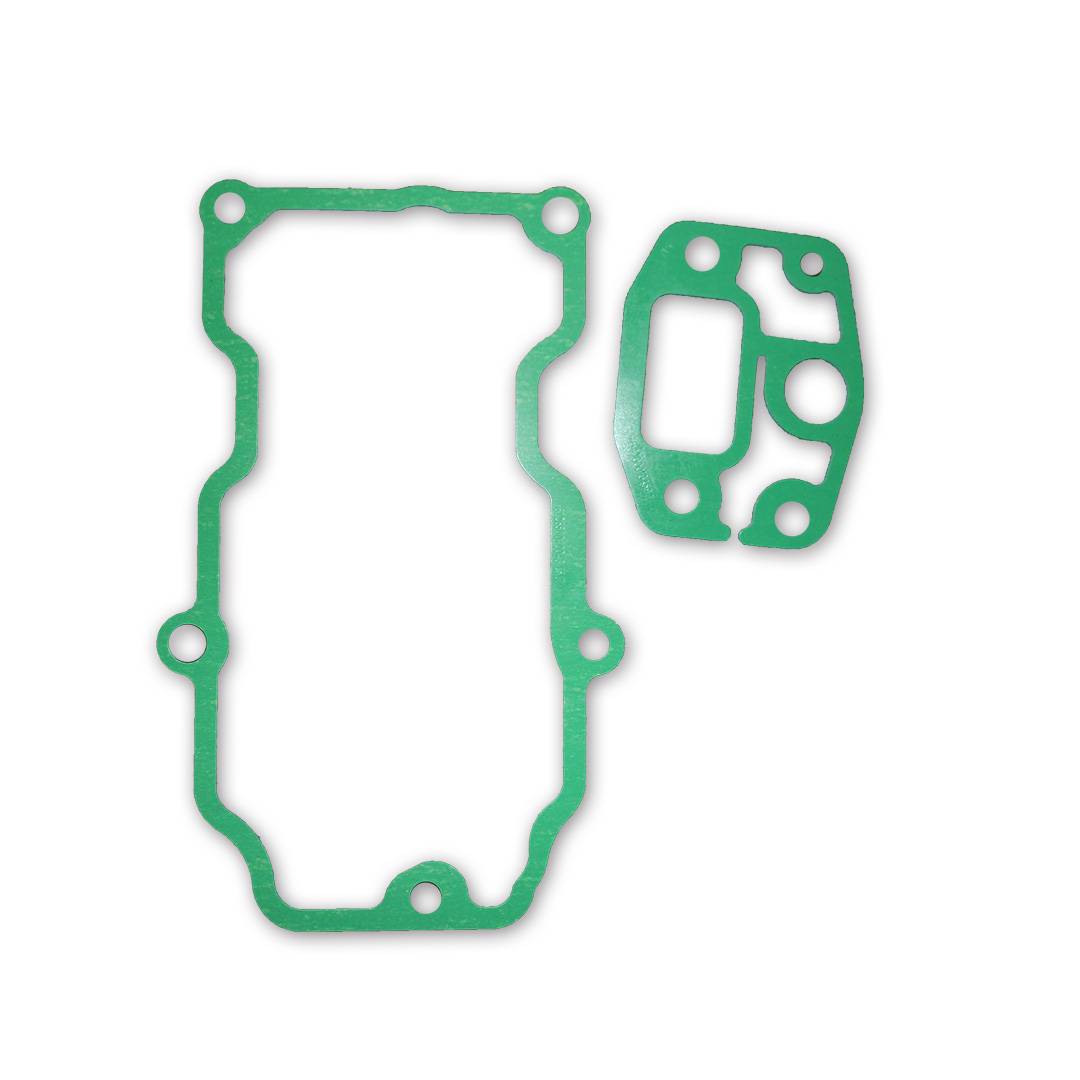

OEM/ODM Factory Gasket Sheet Non Asbestos - FBYS411 Non asbestos sealing sheet – Ishikawa

OEM/ODM Factory Gasket Sheet Non Asbestos - FBYS411 Non asbestos sealing sheet – Ishikawa Detail:

Features

Excellent temperature resistance

Good processing and adaptability

Can be used as an alternative to flexible graphite plates

Can be made into a sprint composite board

Asbestos-free confirmation and ROHS certification by a third party

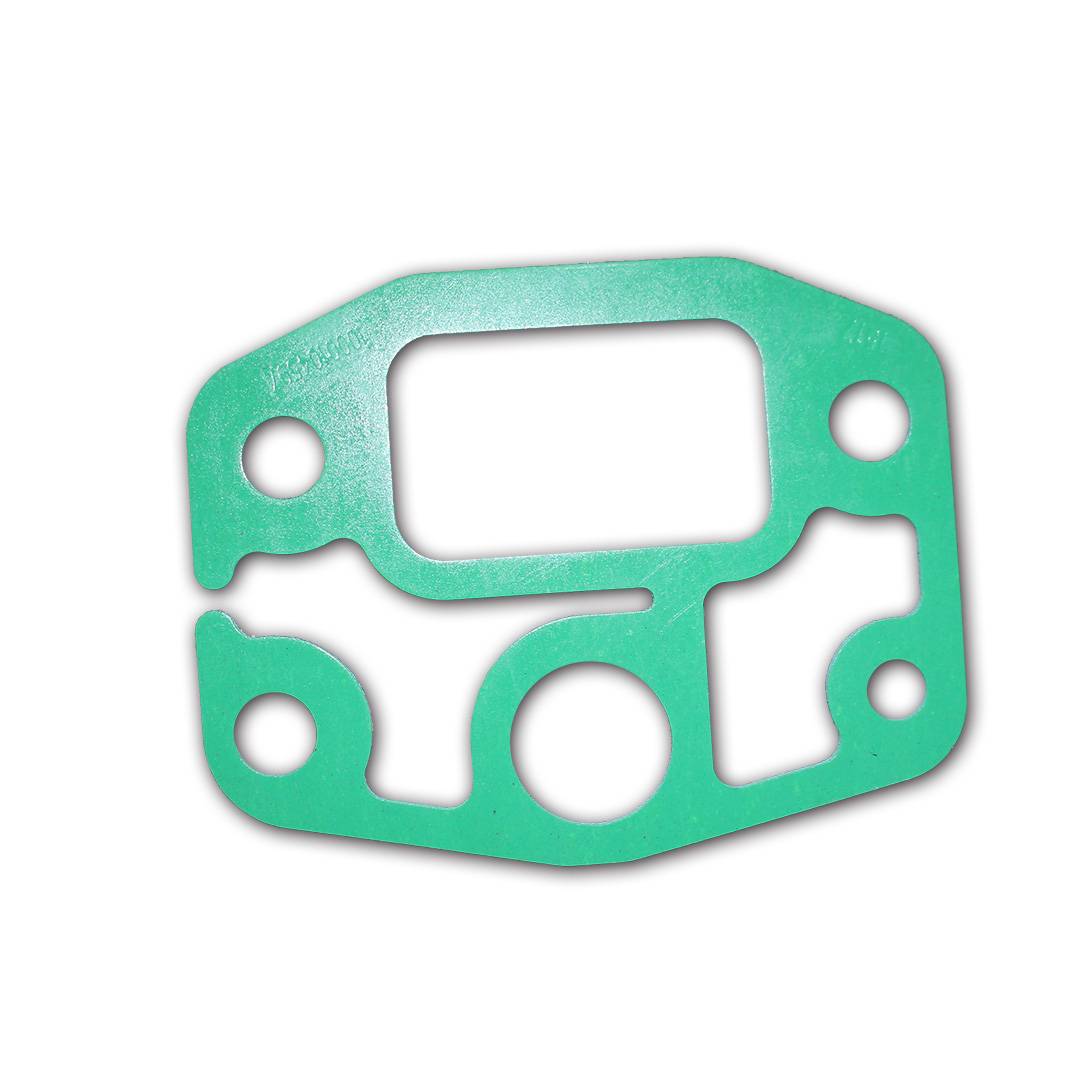

Product use

Recommended for automotive, general purpose exhaust end sealing liner materials

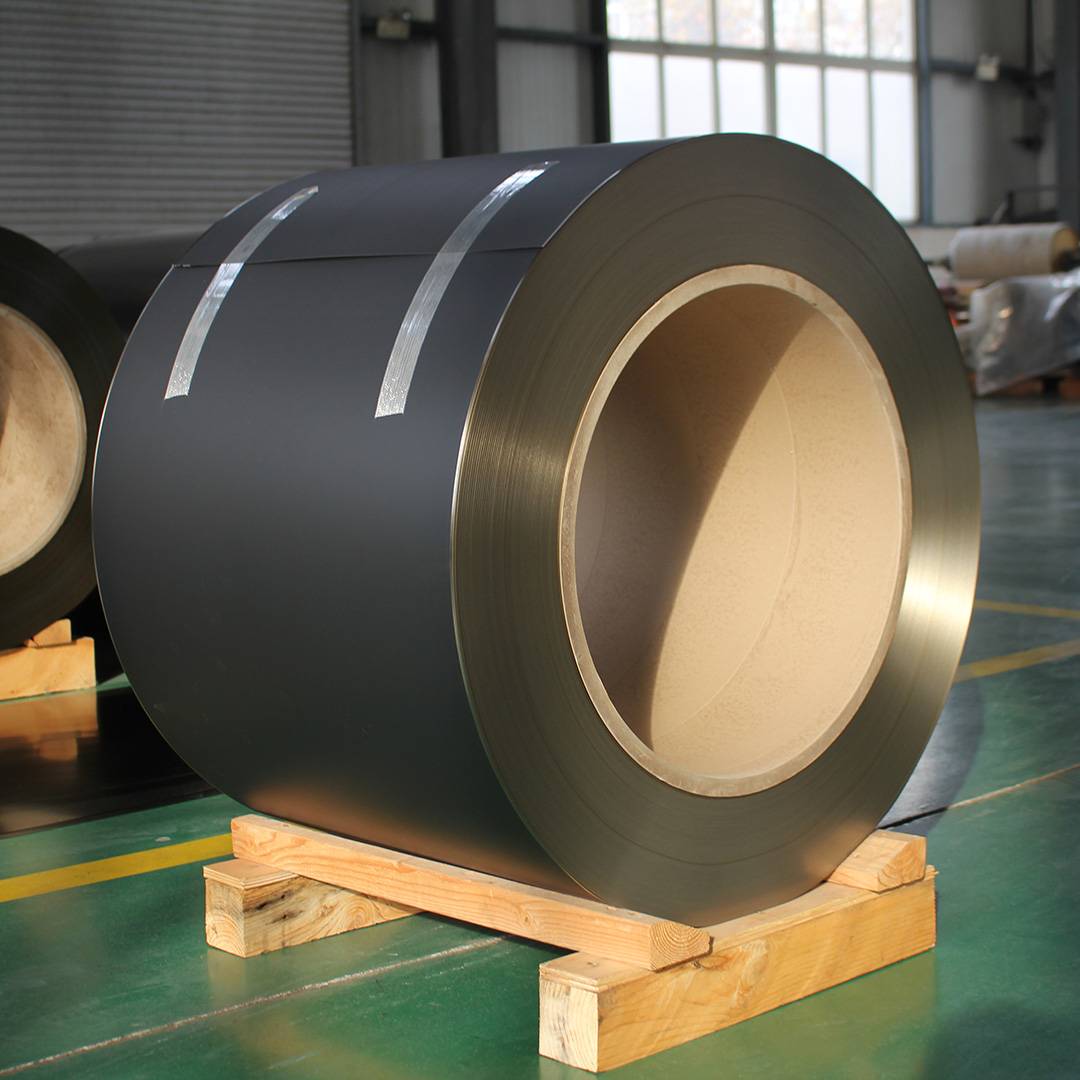

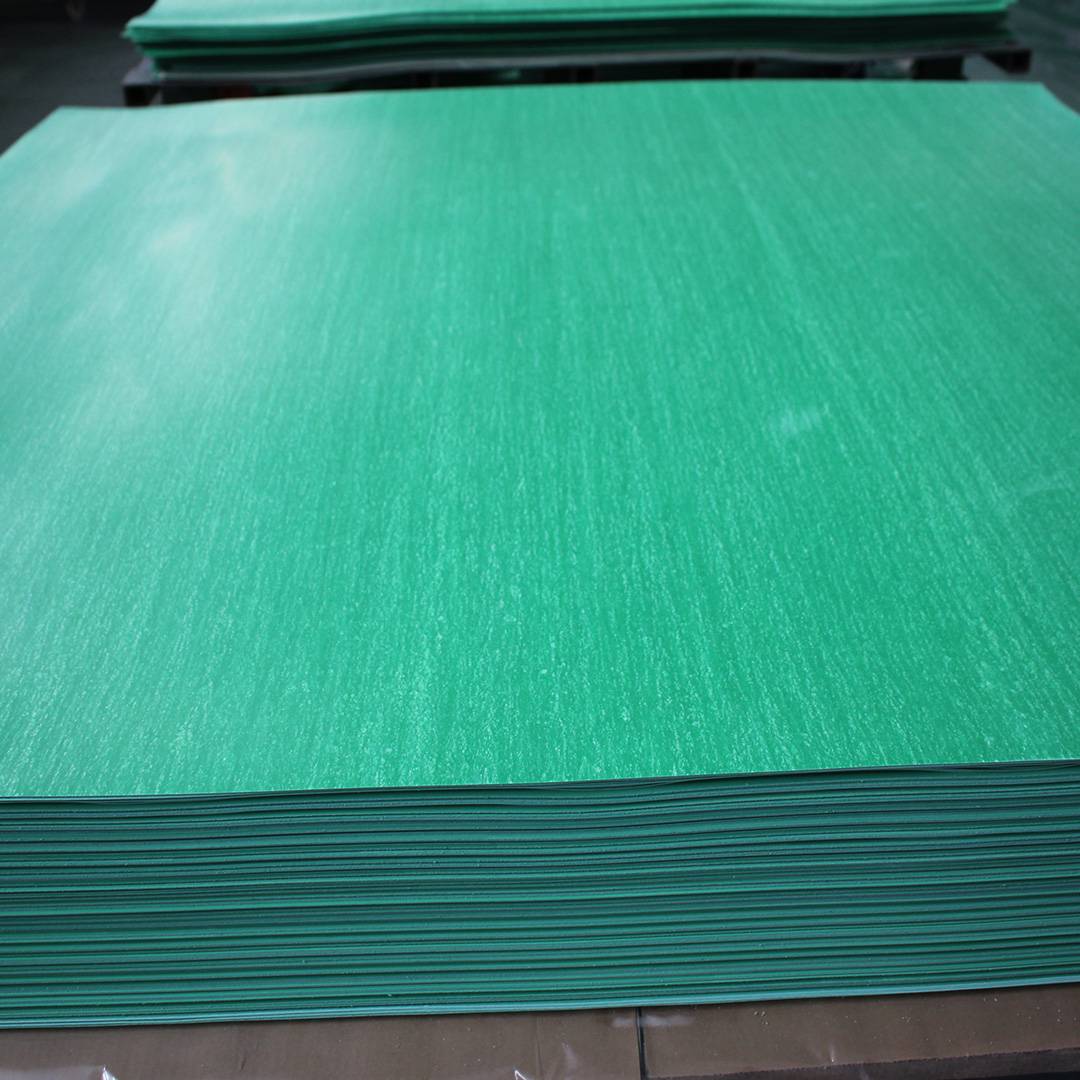

Rules

Sheets: length ≤1150mm,width ≤1150mm, thickness 0.5 to 2.0mm

Special specifications can be agreed with the customer

Physical performance

|

Test conditions |

Pilot project |

Standard |

|

100°C×1h 。 |

The horizontal stretch strength Mpa≥ |

2.0。 |

|

100°C×1h 。 |

Dense g/cm3 |

1.0±0.1 。 |

|

100°C×1h 。 |

The rate of contraction % |

40±7 。 |

| Rebound rate % % |

6。 |

|

|

550°C×1h 。 |

Burn loss % % |

35。 |

|

100°C×22h 。 |

Creep relaxation rate % %≤ |

30。 |

|

Distilled water. |

The thickness change rate %≤ |

15。 |

| Weight change rate %≤ |

45。 |

|

|

Water : glycol is 1:1 100°C×5h 。 |

The thickness change rate %≤ |

15。 |

| Weight change rate %≤ |

60。 |

|

|

ASTM FUEL B。 |

The thickness change rate %≤ |

10。 |

| Weight change rate %≤ |

45。 |

|

|

IRM 903 s standard oil |

The thickness change rate %≤ |

15。 |

| Weight change rate %≤ |

50。 |

|

|

Heat-resistant aging |

The rate of contraction % |

30±7 。 |

| Rebound rate % % |

30。 |

|

| The thickness change rate %≤ |

0±5 。 |

|

| Weight change rate %≤ |

0±3 。 |

Product detail pictures:

Related Product Guide:

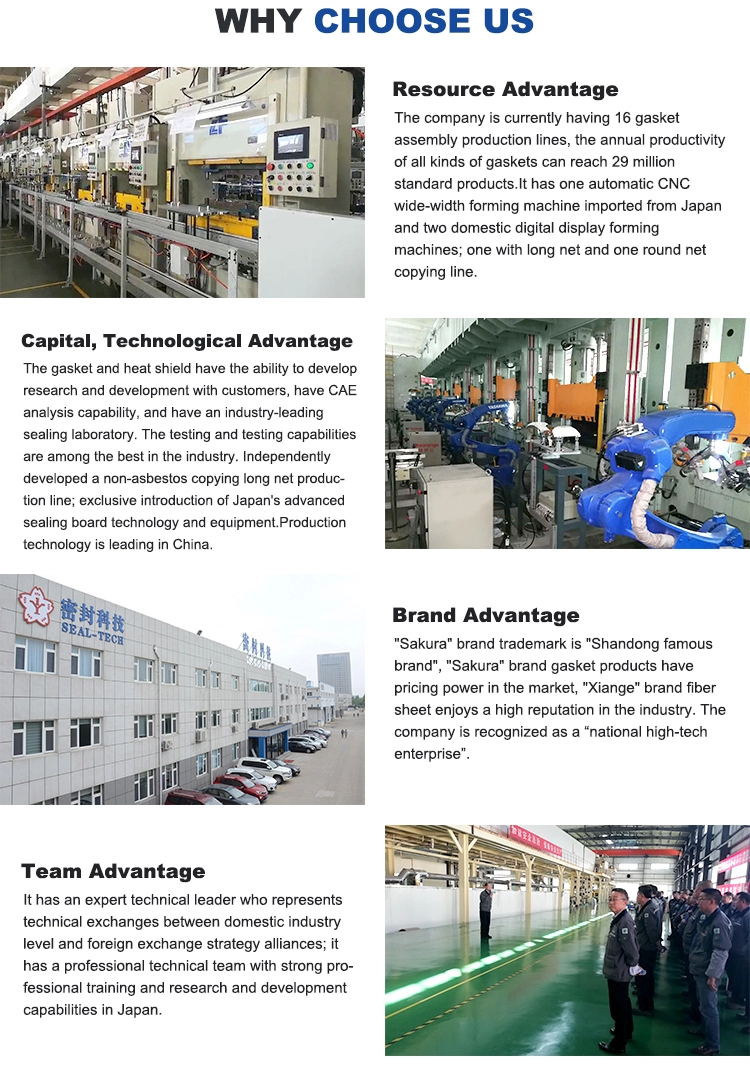

The corporate upholds the philosophy of "Be No.1 in excellent, be rooted on credit rating and trustworthiness for growth", will keep on to serve outdated and new clients from home and abroad whole-heatedly for OEM/ODM Factory Gasket Sheet Non Asbestos - FBYS411 Non asbestos sealing sheet – Ishikawa, The product will supply to all over the world, such as: Monaco, Austria, moldova, After years' creating and developing, with the advantages of trained qualified talents and rich marketing experience, outstanding achievements were gradually made. We get good reputation from the customers due to our good solutions quality and fine after-sale service. We sincerely wish to create a more prosperous and flourishing future together with all the friends home and abroad!

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.