Manufacturer of Composite Cylinder-Head Gaskets Material - Rubber Coated Metal – UFM2520 – Ishikawa

Manufacturer of Composite Cylinder-Head Gaskets Material - Rubber Coated Metal – UFM2520 – Ishikawa Detail:

Construction

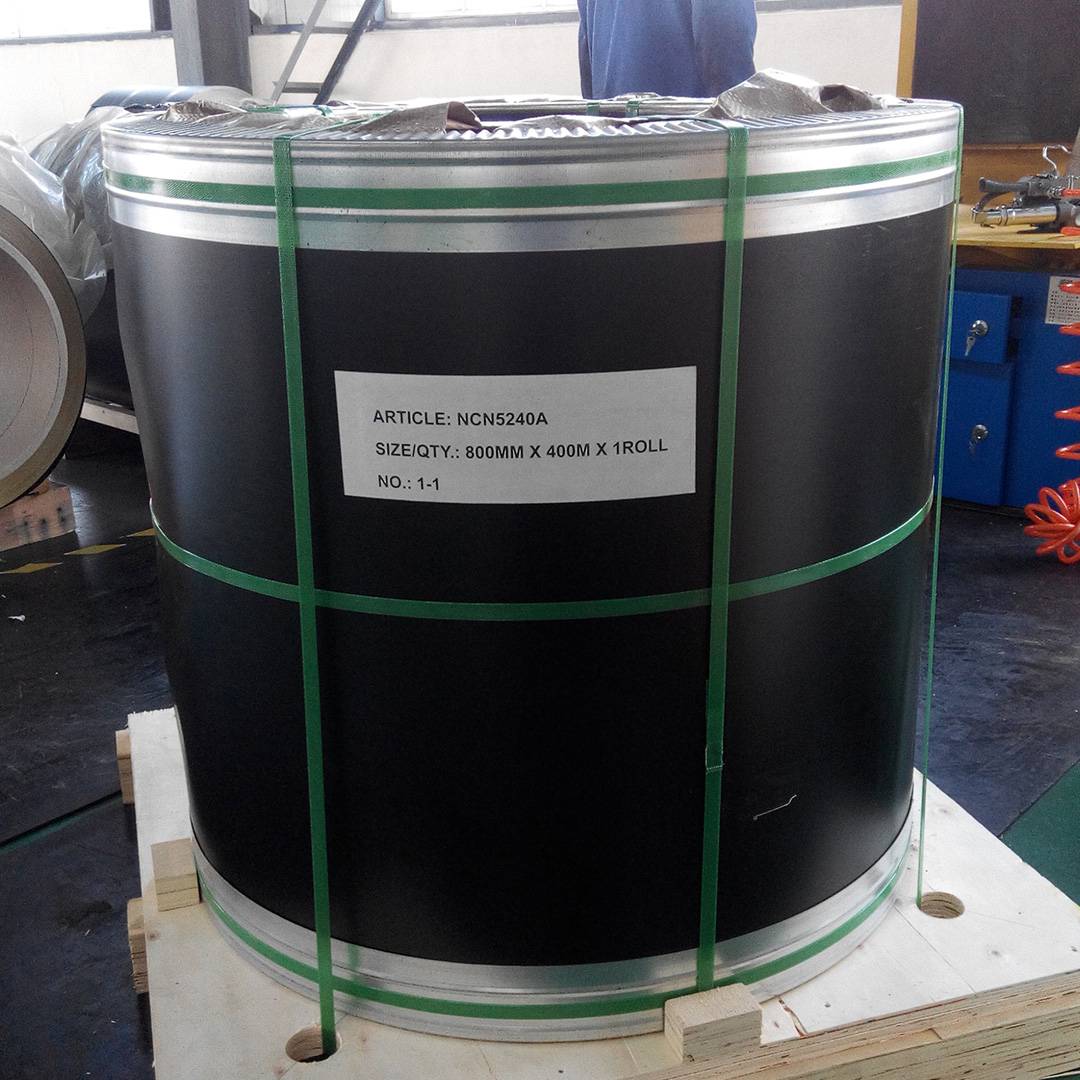

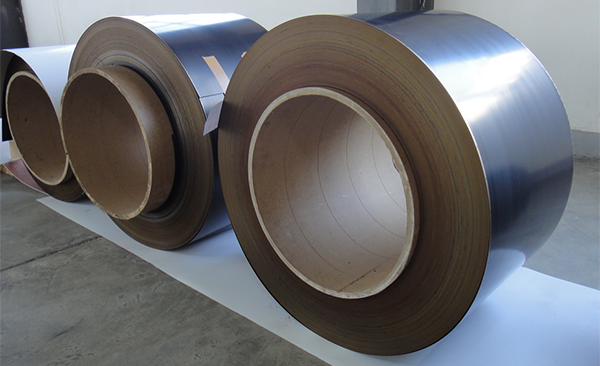

The First RCM Production Line in China

|

Type |

Total thickness |

Rubber thickness |

Metal base |

|

|

type |

Thickness(mm) |

|||

|

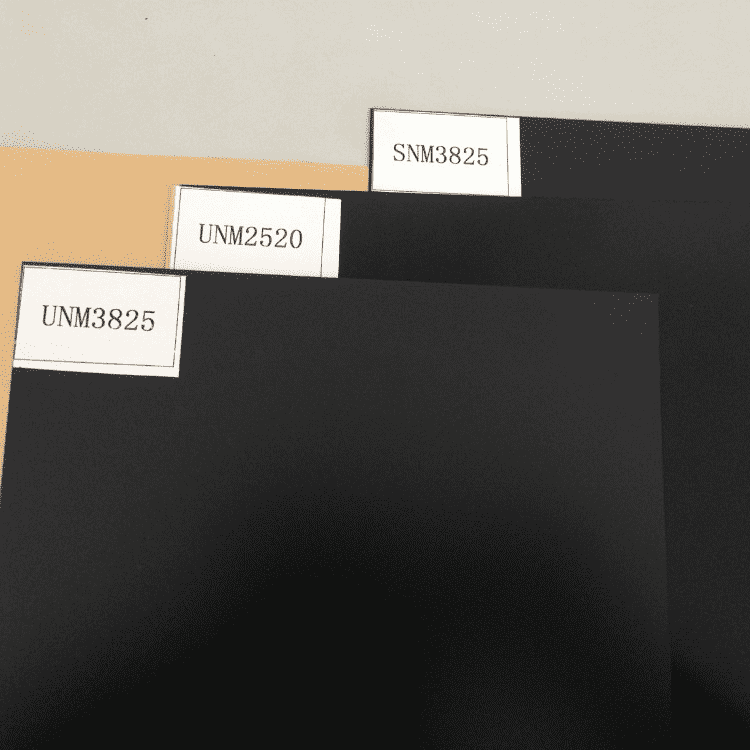

UFM2520 |

0.25 |

0.025*2sides |

SUS301,SUS304 |

0.20 |

|

UFM3025 |

0.30 |

0.025*2sides |

SUS301,SUS304 |

0.25 |

|

UFM3530 |

0.35 |

0.025*2sides |

SUS301,SUS304 |

0.30 |

Specifications

The production line is 360 meters long in total and 20 meters width, the key equipments are from France, Germany and Japan.

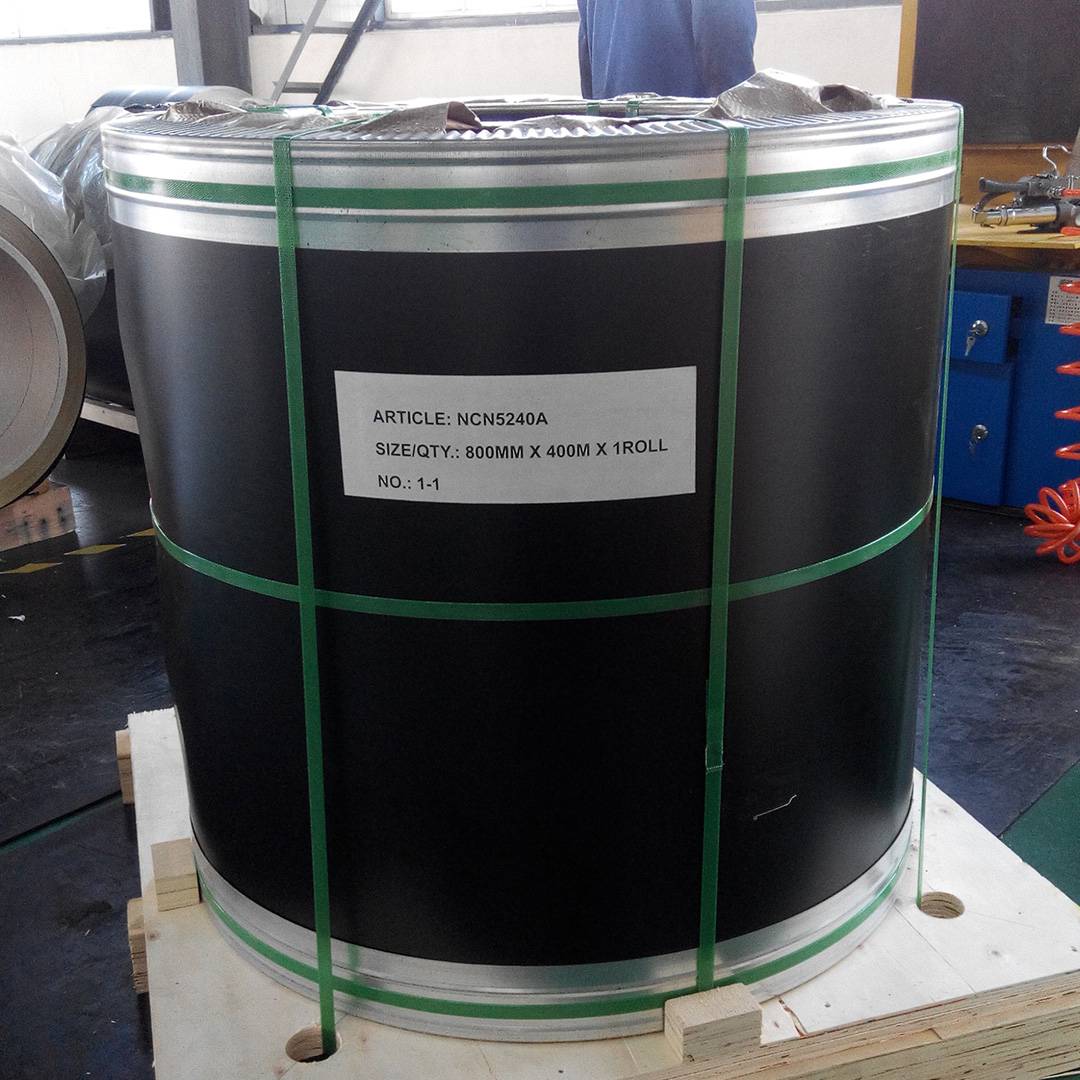

Product Dimension

Available metal substrates thickness are between 0.2mm-0.8mm.Max width is 800mm.Rubber coating thickness is between 0.02-0.12mm single and double-side rubber coated metal roll material can meet the requirement of different customers.

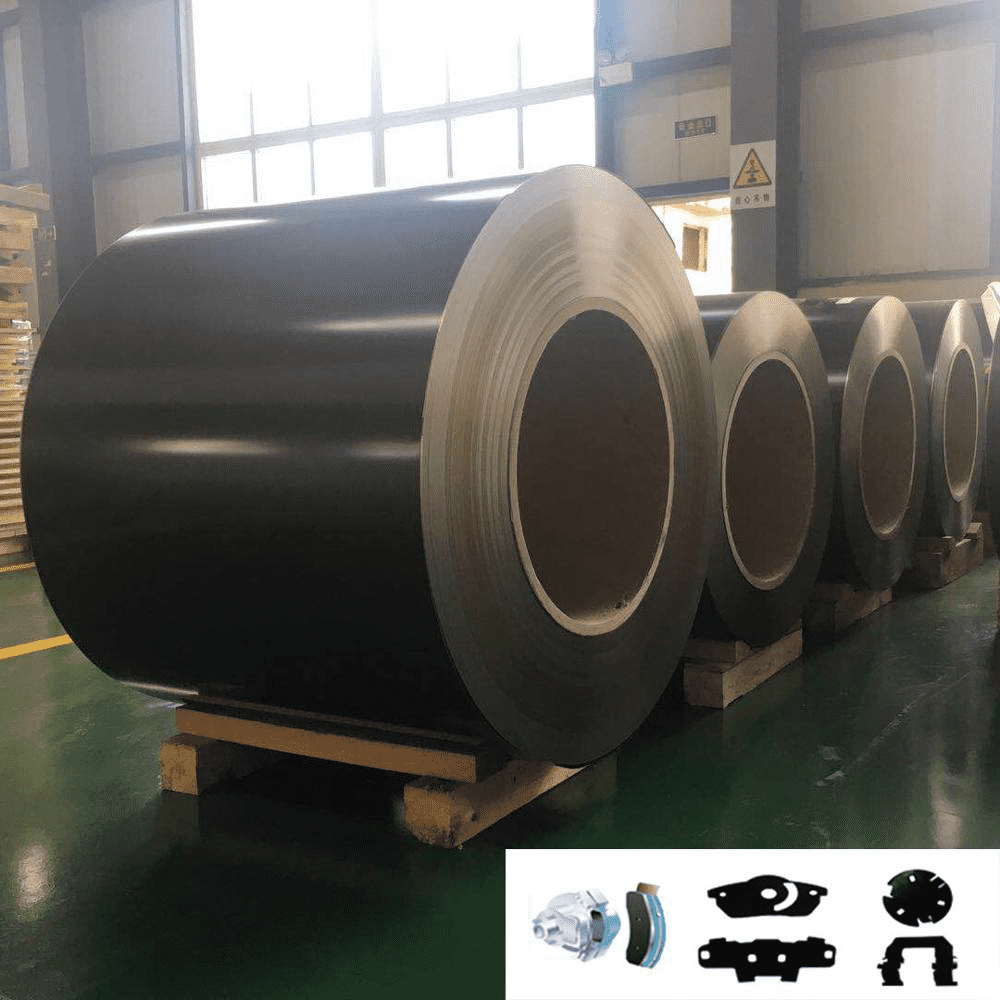

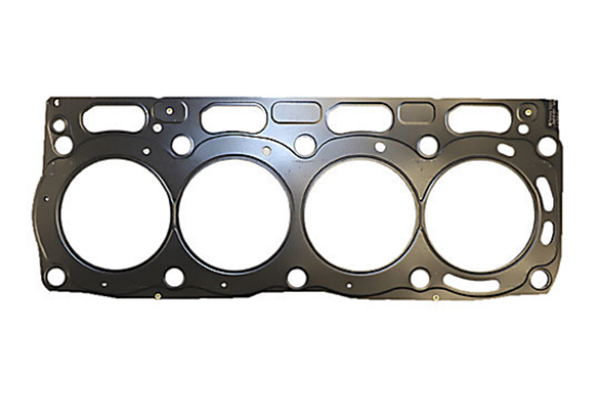

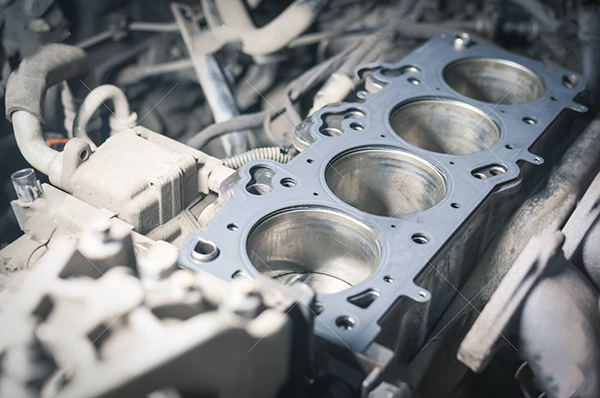

Main Application

Rubber coated metal materials gives the consideration of both metal rigidity and rubber elasticity for its special construction. So this material is suitable for automobile and motorcycle cylinder head gaskets, accessory gaskets, refrigeration and compressor gasket with its excellent sealability, compression and recovery property, good creep relaxation and fluid resistance and durability, good coolant and low temperature resistance performance.

Characteristics

* Excellent high and low temperature resistance-working temperature is between -40℃ and 260℃;

* Good sealability and suitable for gas and fluid sealability;

* Excellent mechanical performance. Tensile strength can reach 100MPa.Excellent compression, recovery and stress relaxation performance;

* Good fluid resistance and suitable for various complicated environment, especially suitable for mechanical oil, antifreeze and coolant;

* Good anti-ageing property

* Fine processing properties and can be processed automatically in continuous way which keep the same lot of gaskets in good consistence with high efficiency.

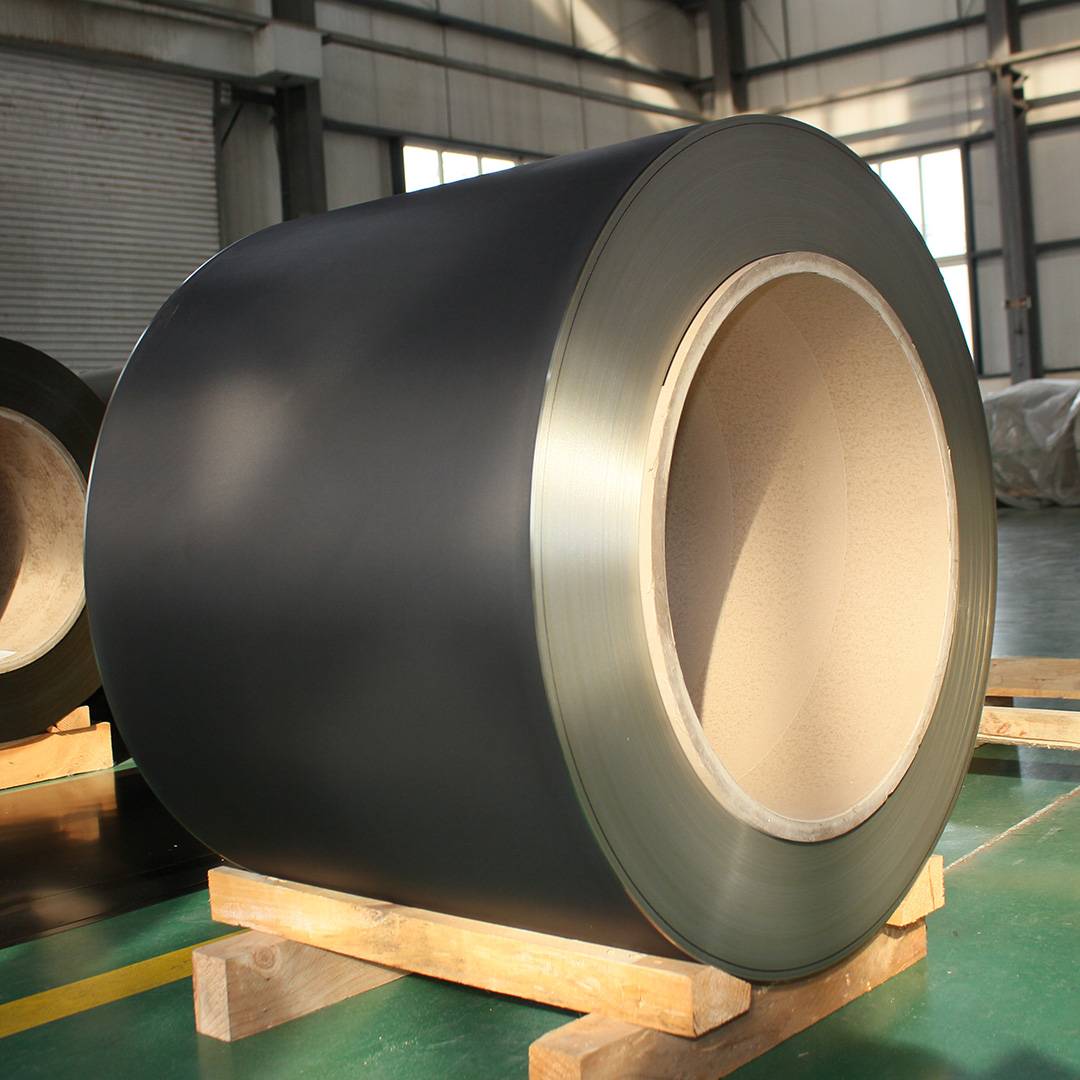

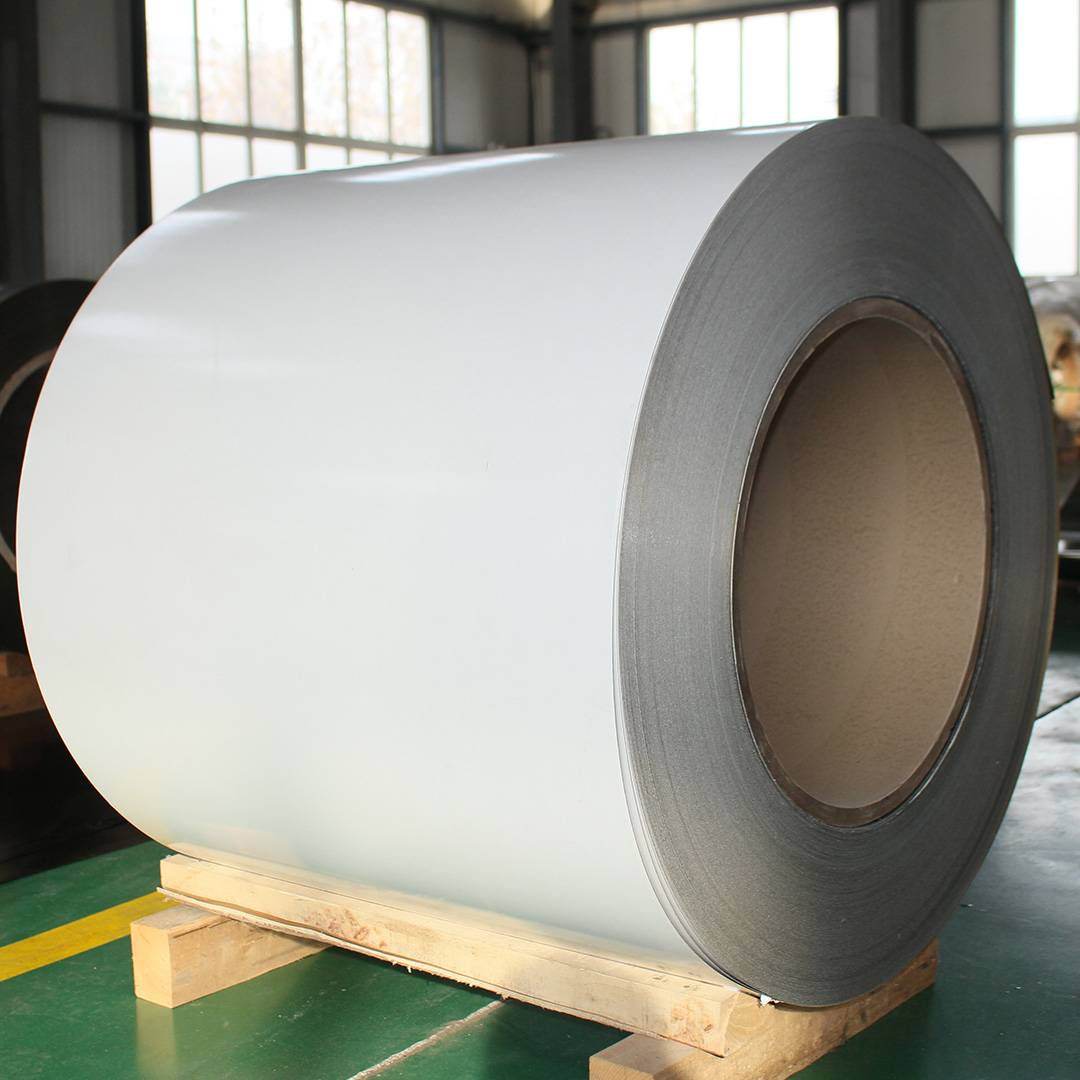

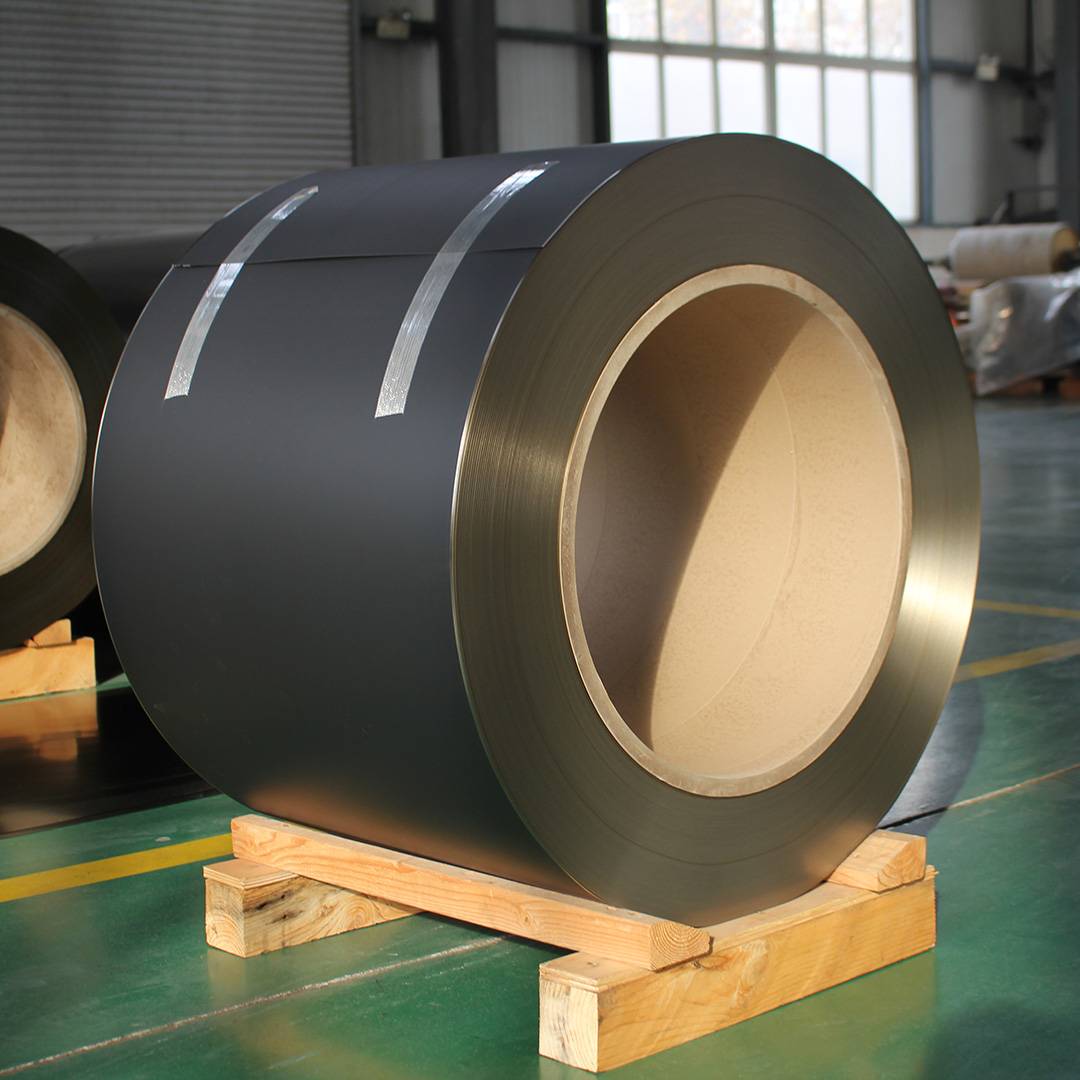

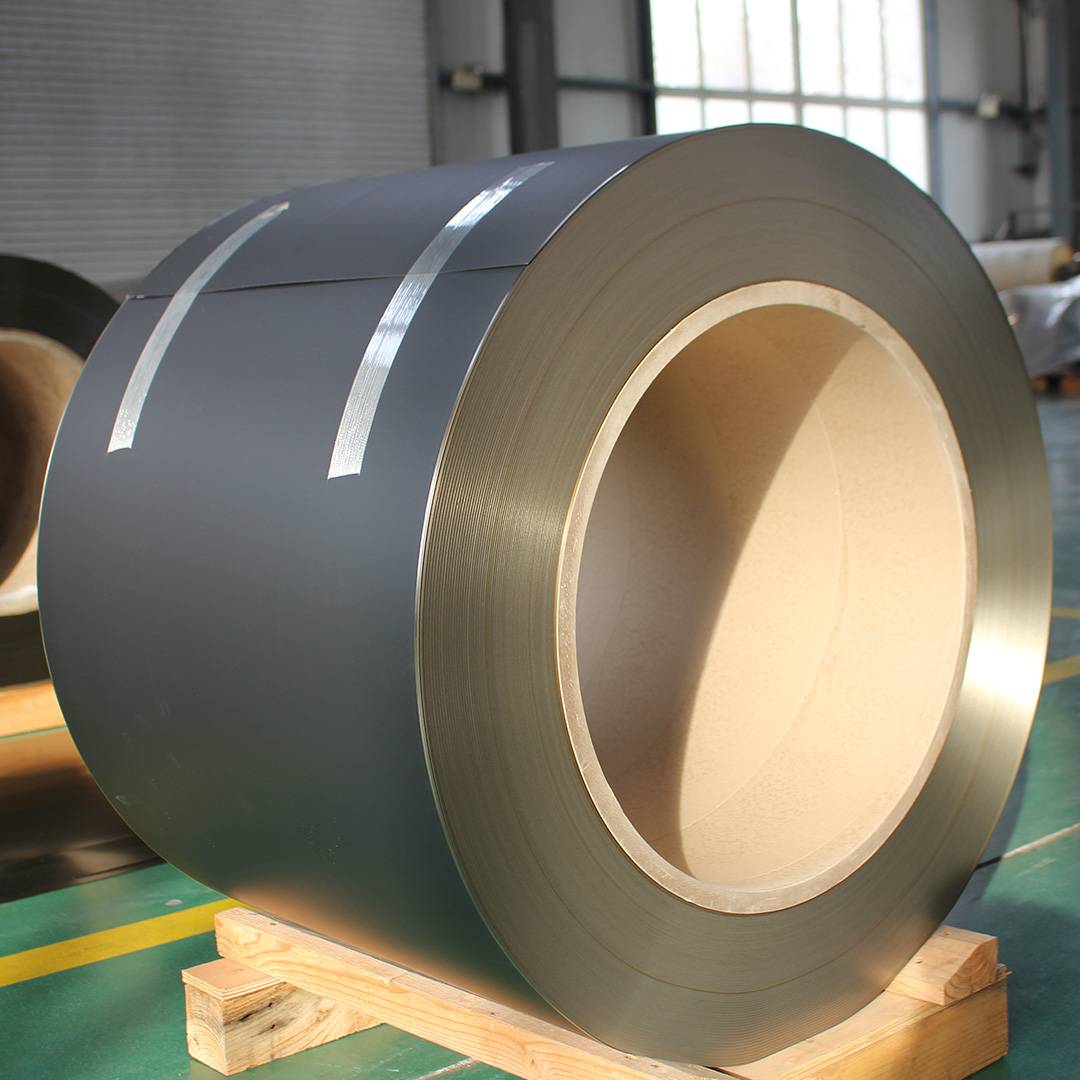

Product detail pictures:

Related Product Guide:

We have been experienced manufacturer. Wining the majority of your crucial certifications of its market for Manufacturer of Composite Cylinder-Head Gaskets Material - Rubber Coated Metal – UFM2520 – Ishikawa, The product will supply to all over the world, such as: Montpellier, Japan, Durban, Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.