Hot Selling for Rubber Coated Stainless Steel Coil Gasket Material - Rubber Coated Metal UNX5045-1 – Ishikawa

Hot Selling for Rubber Coated Stainless Steel Coil Gasket Material - Rubber Coated Metal UNX5045-1 – Ishikawa Detail:

Construction

Specifications

|

type |

Total thickness |

Rubber thickness |

Metal base |

|

|

type |

Thickness(mm) |

|||

|

UNX3025-1 |

0.30 |

0.05*single side |

SUS301 |

0.25 |

|

UNX4035-1 |

0.40 |

0.05*single side |

SUS301 |

0.35 |

|

UNX5045-1 |

0.50 |

0.05*single side |

SUS301 |

0.45 |

|

UNX6055-1 |

0.60 |

0.05*single side |

SUS301 |

0.55 |

The First RCM Production Line in China

The production line is 360 meters long in total and 20 meters width, the key equipments are from France, Germany and Japan.

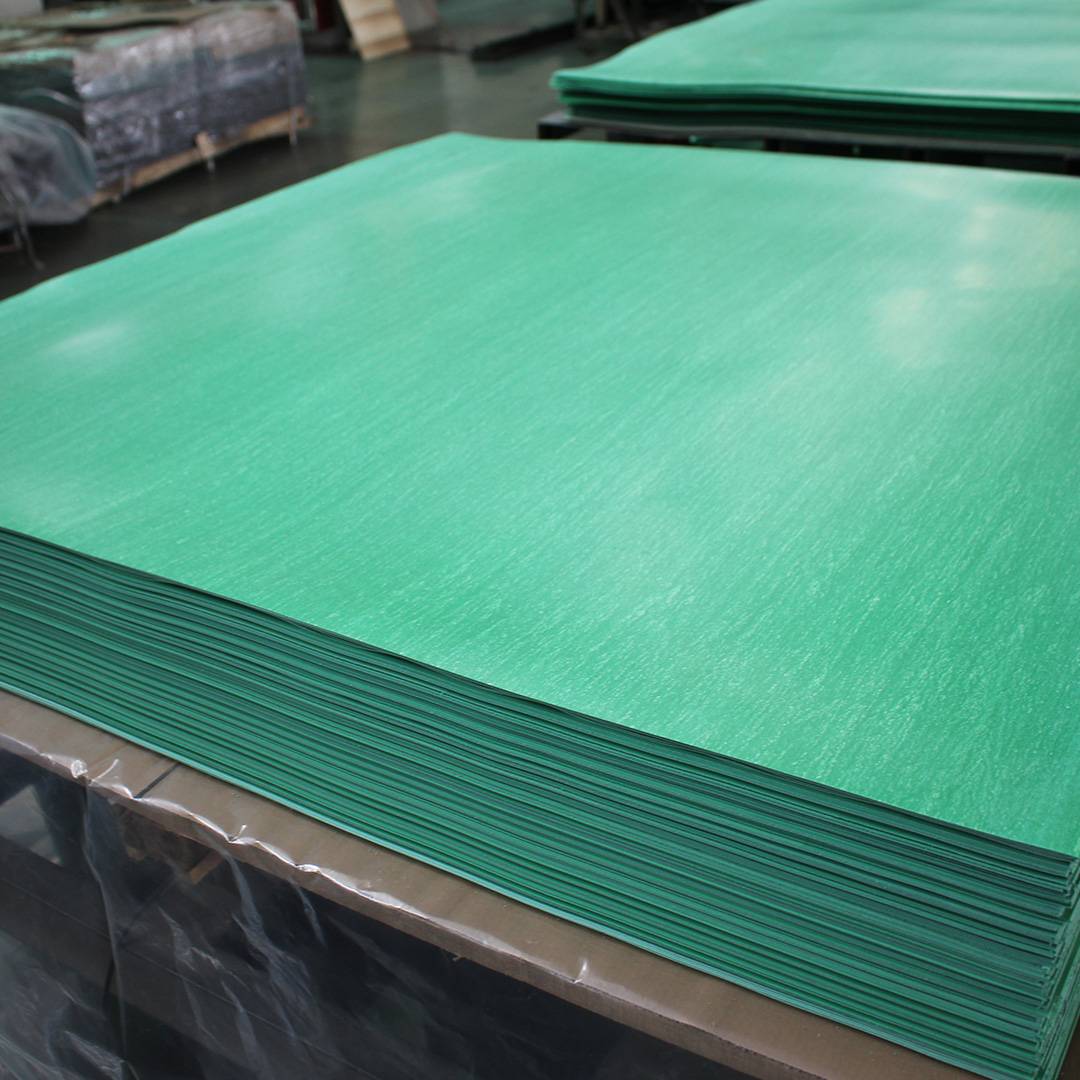

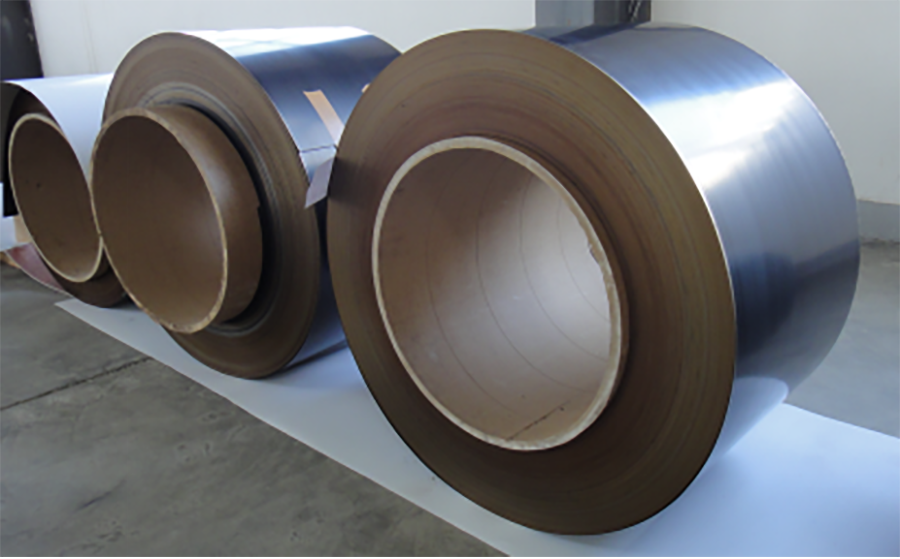

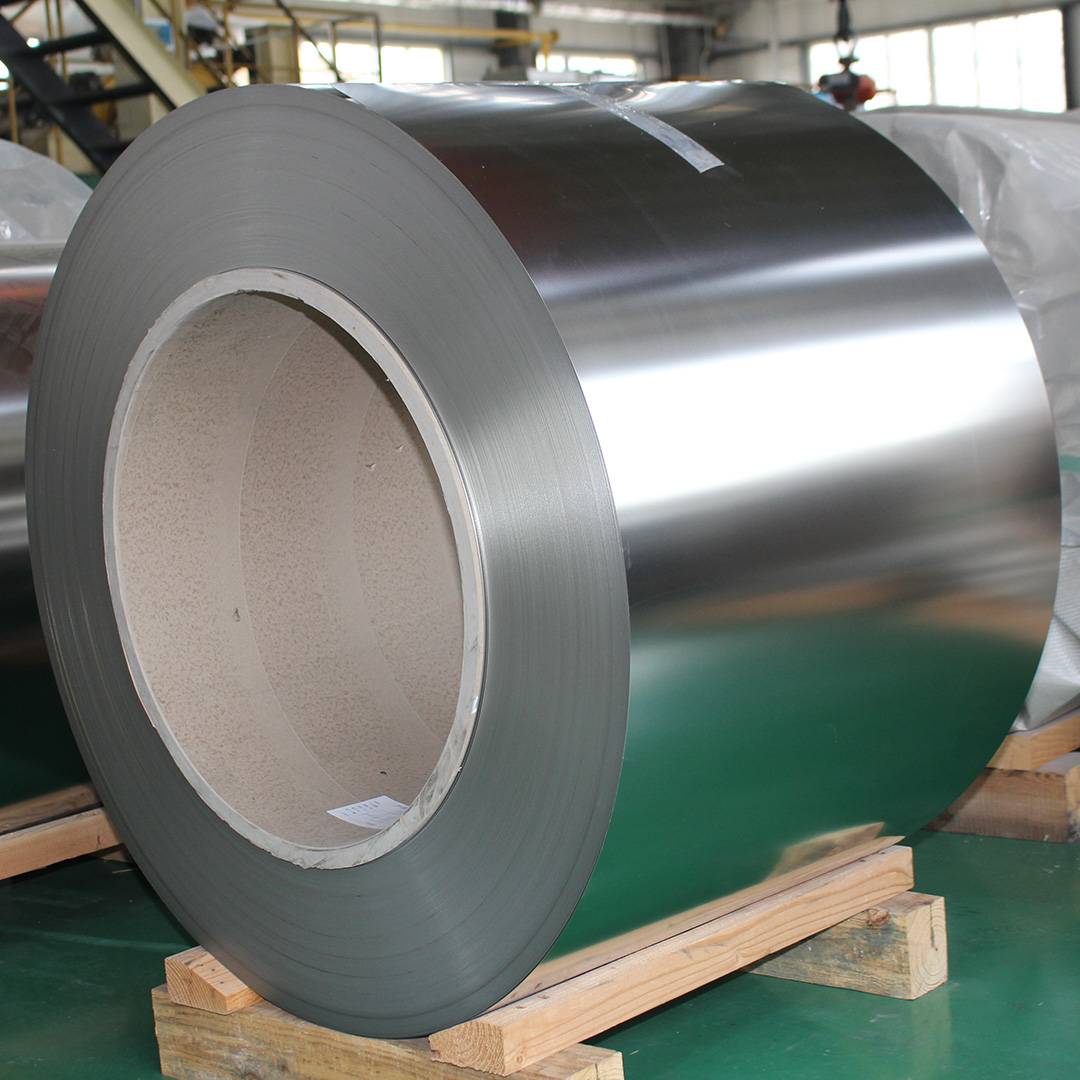

Product Dimension

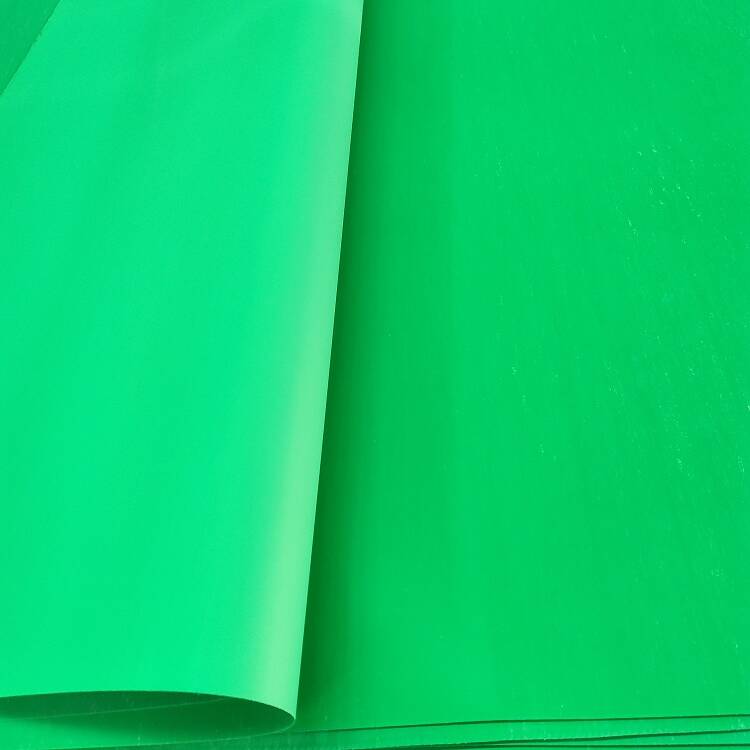

Available metal substrates thickness are between 0.2mm-0.8mm.Max width is 800mm.Rubber coating thickness is between 0.02-0.12mm single and double-side rubber coated metal roll material can meet the requirement of different customers.

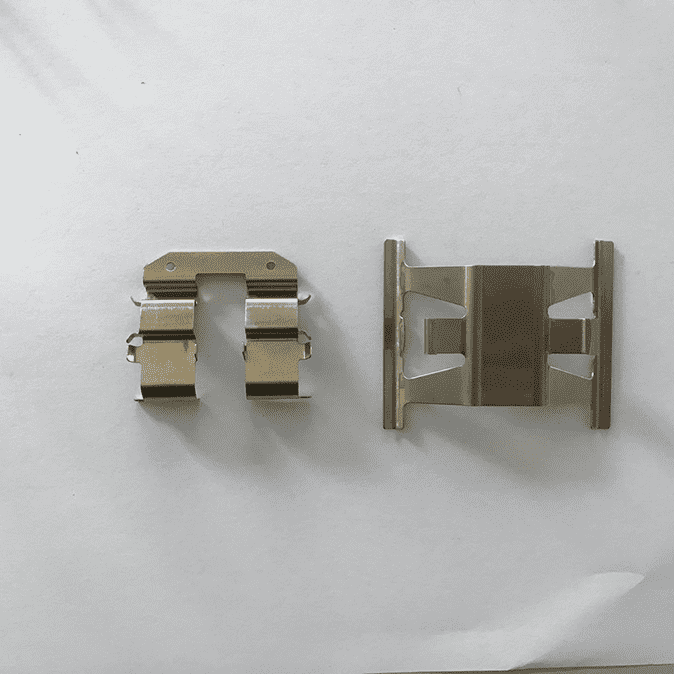

Main Application

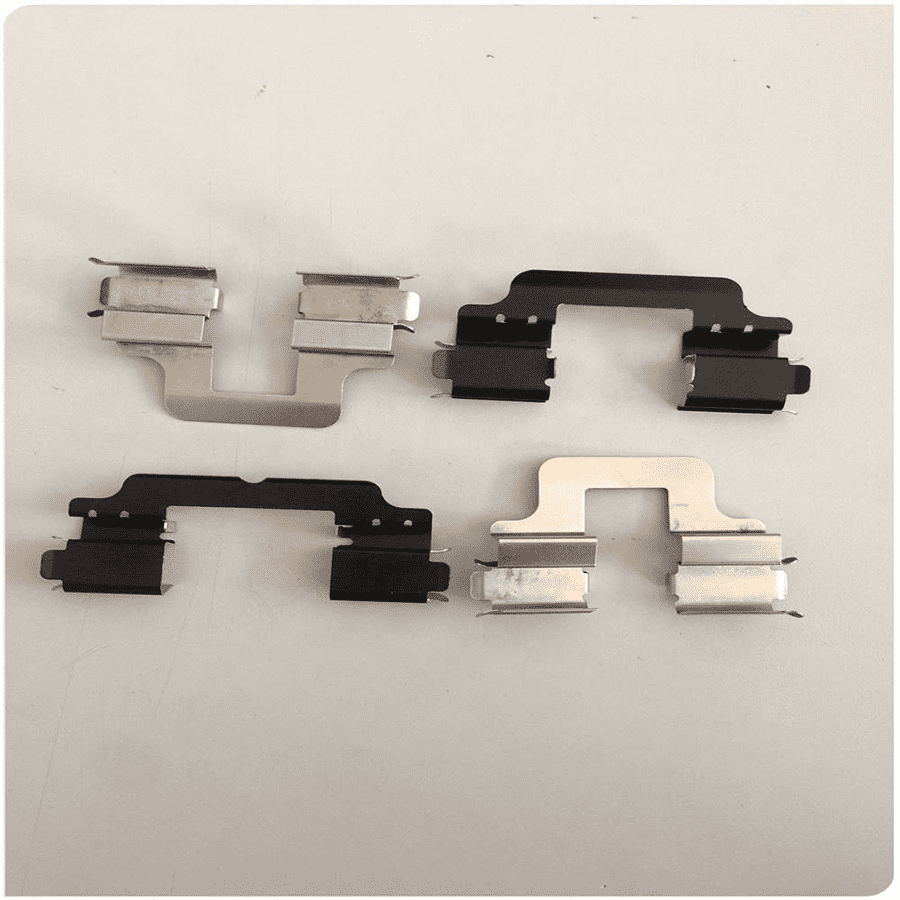

Abutment clips with adhesion are critical to a smooth operation of the brake system. Our products can effectively suppress the sliding noise; improve the overall noise reduction performance of the braking system. It can create the possibility of providing a comfortable and quiet drive for you.

|

Serial No. |

Item |

Test condition |

Standard |

|

1 |

metal base | Vickers hardness tester | stainless steel |

|

2 |

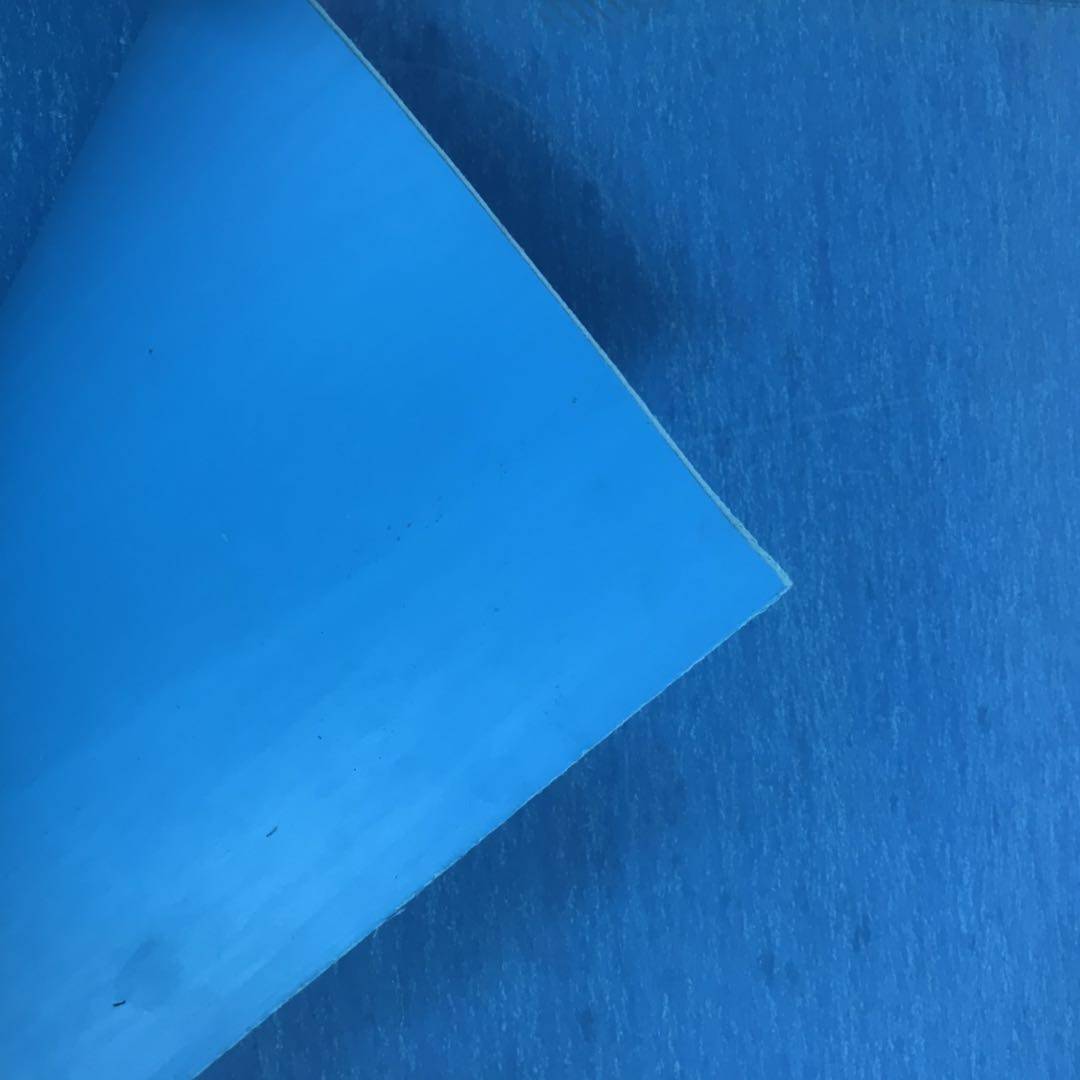

appearance | visual inspection | flat surface,no impurities, no bubble |

|

3 |

pencil hardness | pencil hardness tester | above 2H |

|

4 |

adhesive force | spiral scoring test | above grade 2 |

|

5 |

anti MIBK test | immerse for 10 minutes | cannot be rubbed out by eraser |

|

6 |

Salt spray resistance test | immerse for 240h | no peeling ,no bubble |

|

7 |

anti 903# oil test | 150℃×5h | max weight change ratio %≤3 |

| max thickness change ratio % ≤12 | |||

|

8 |

anti-freezer testwater: glycol=1:1 | 120℃×72h | max weight change ratio%≤3 |

| max thickness change ratio%≤12 |

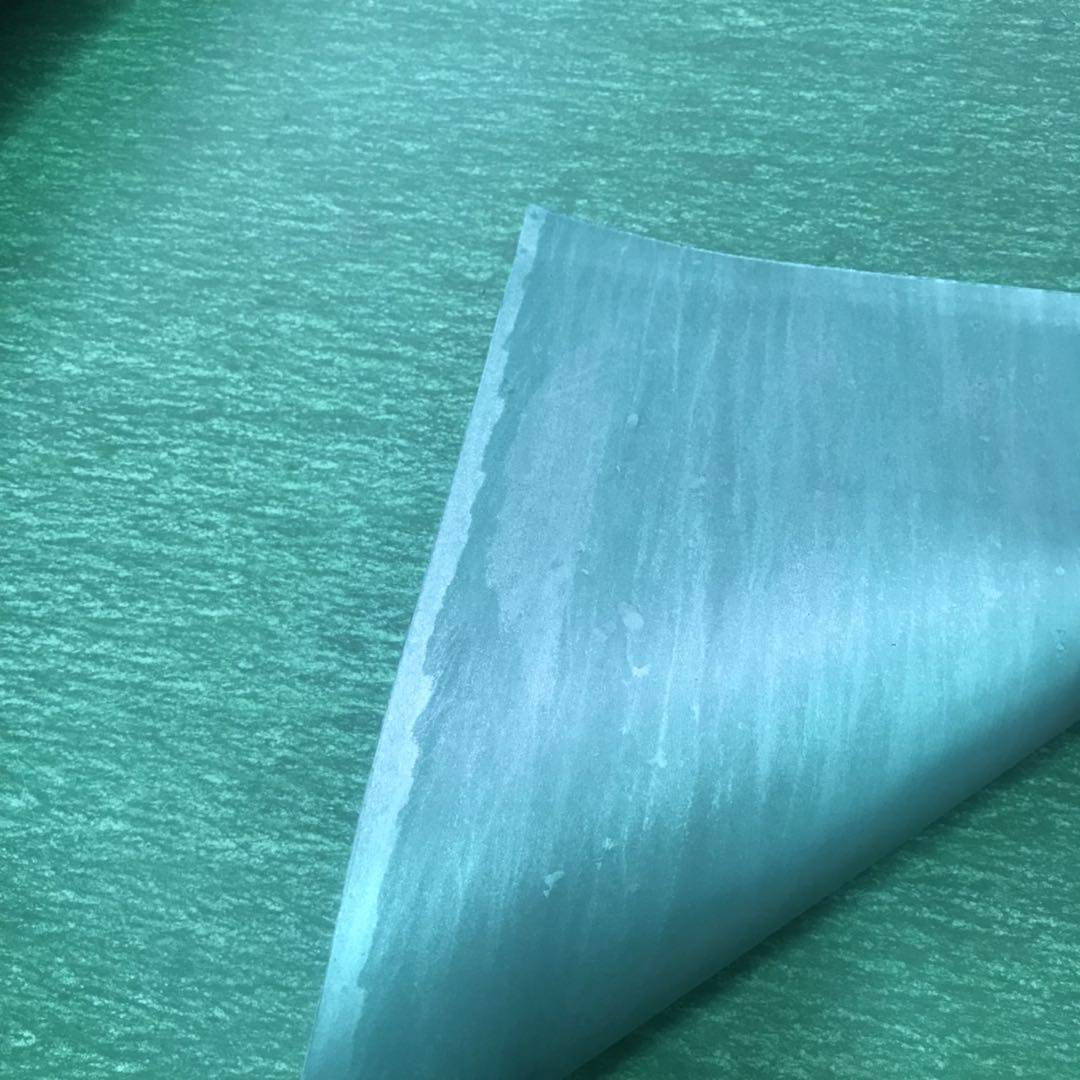

Product detail pictures:

Related Product Guide:

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and service capabilities for Hot Selling for Rubber Coated Stainless Steel Coil Gasket Material - Rubber Coated Metal UNX5045-1 – Ishikawa, The product will supply to all over the world, such as: Portland, Romania, Nepal, With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we are trying our best to be your good partner.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.