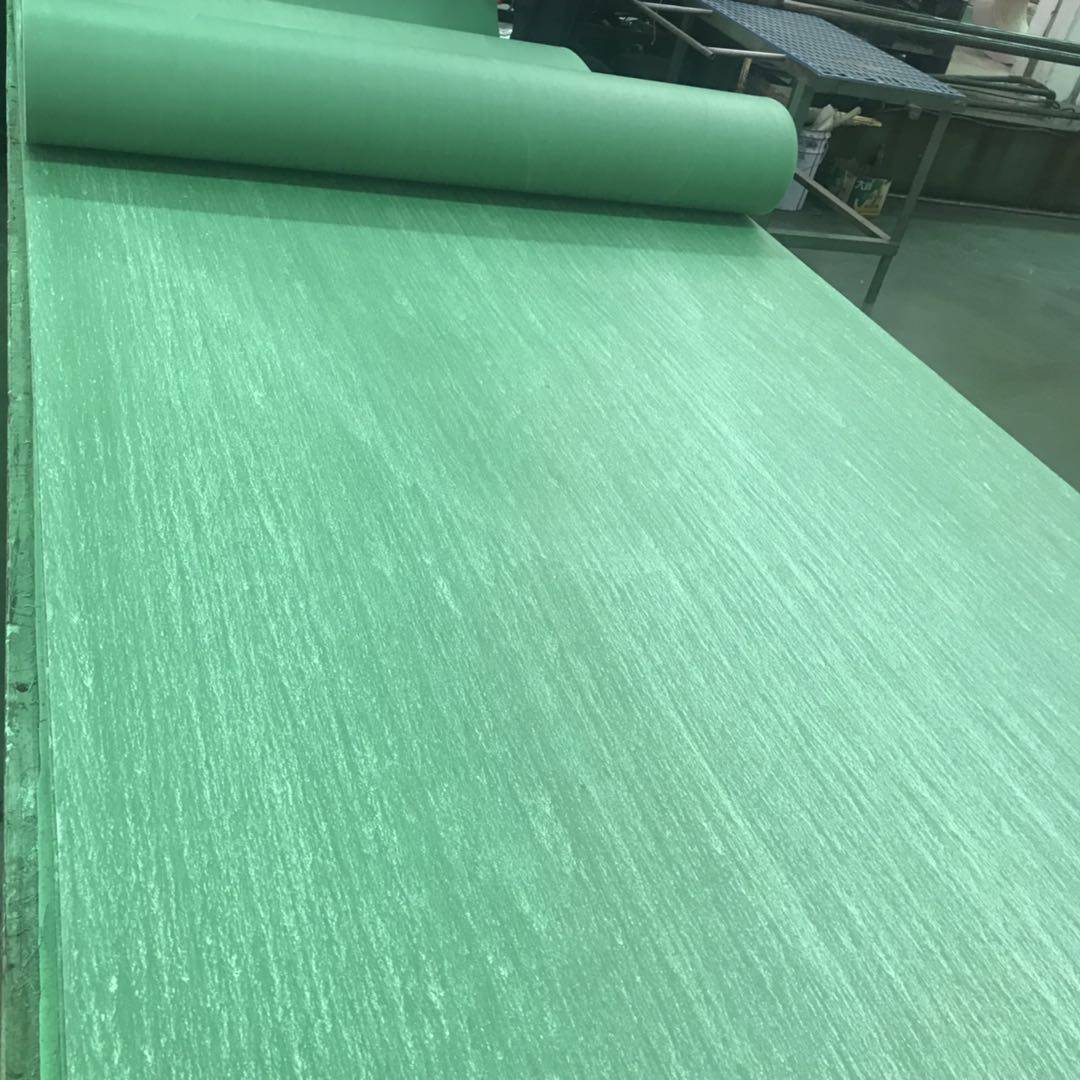

Discount wholesale Gasket Material For Sealing - FBYS411 fiber-reinforced graphite graphite scribe plate – Ishikawa

Discount wholesale Gasket Material For Sealing - FBYS411 fiber-reinforced graphite graphite scribe plate – Ishikawa Detail:

Features

Excellent temperature resistance

Good processing and adaptability

Can be used as an alternative to flexible graphite plates

Can be made into a sprint composite board

Asbestos-free confirmation and ROHS certification by a third party

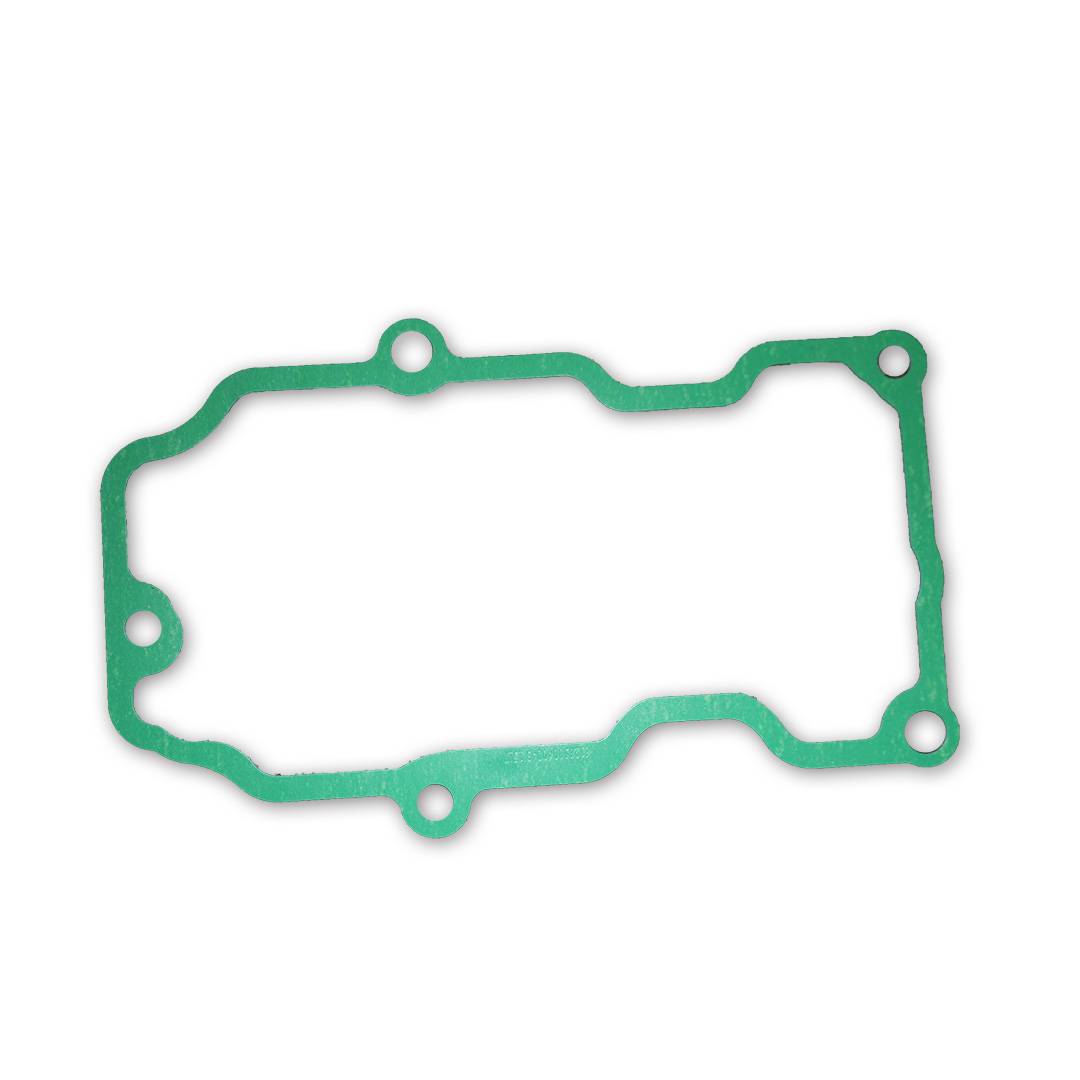

Product use

Recommended for automotive, general purpose exhaust end sealing liner materials

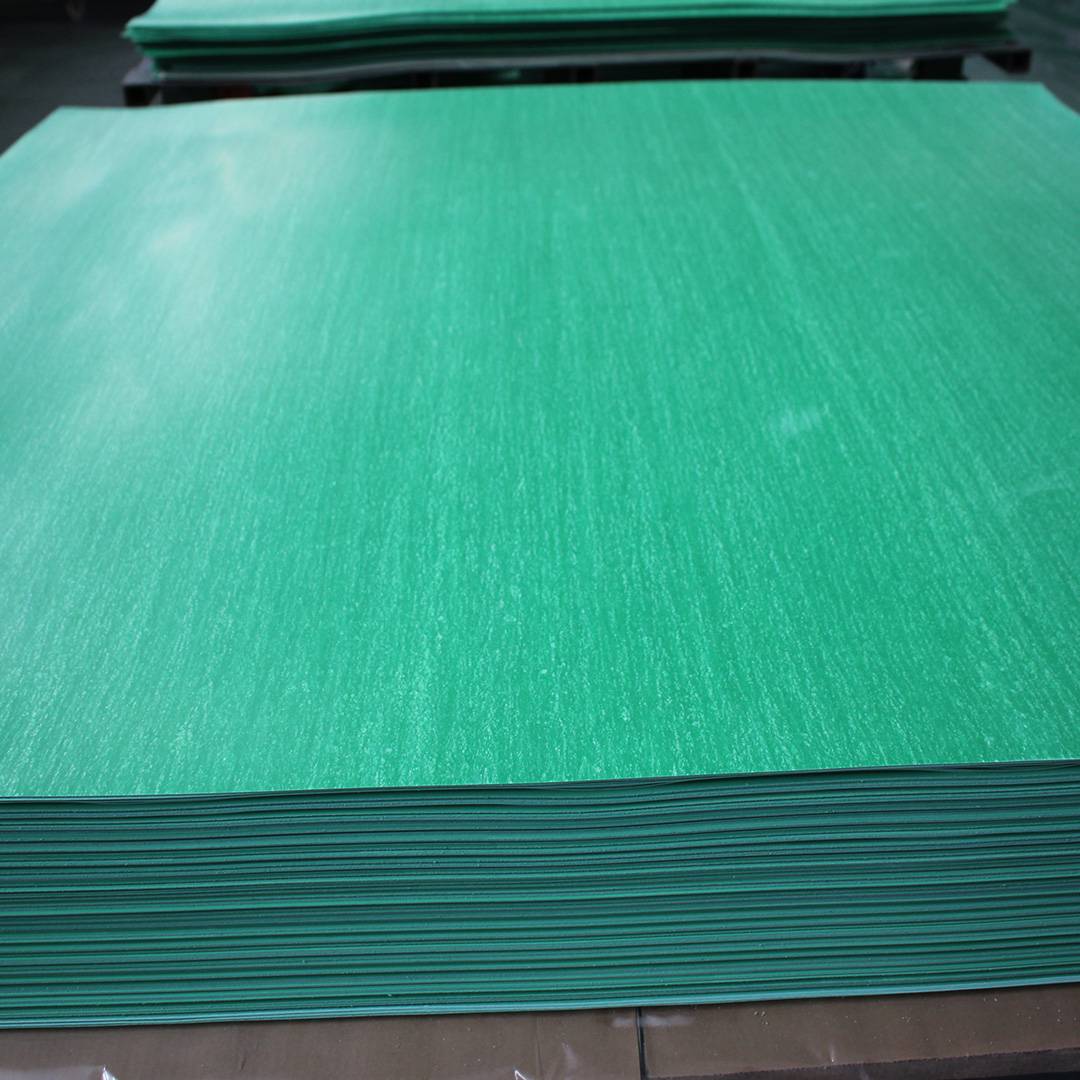

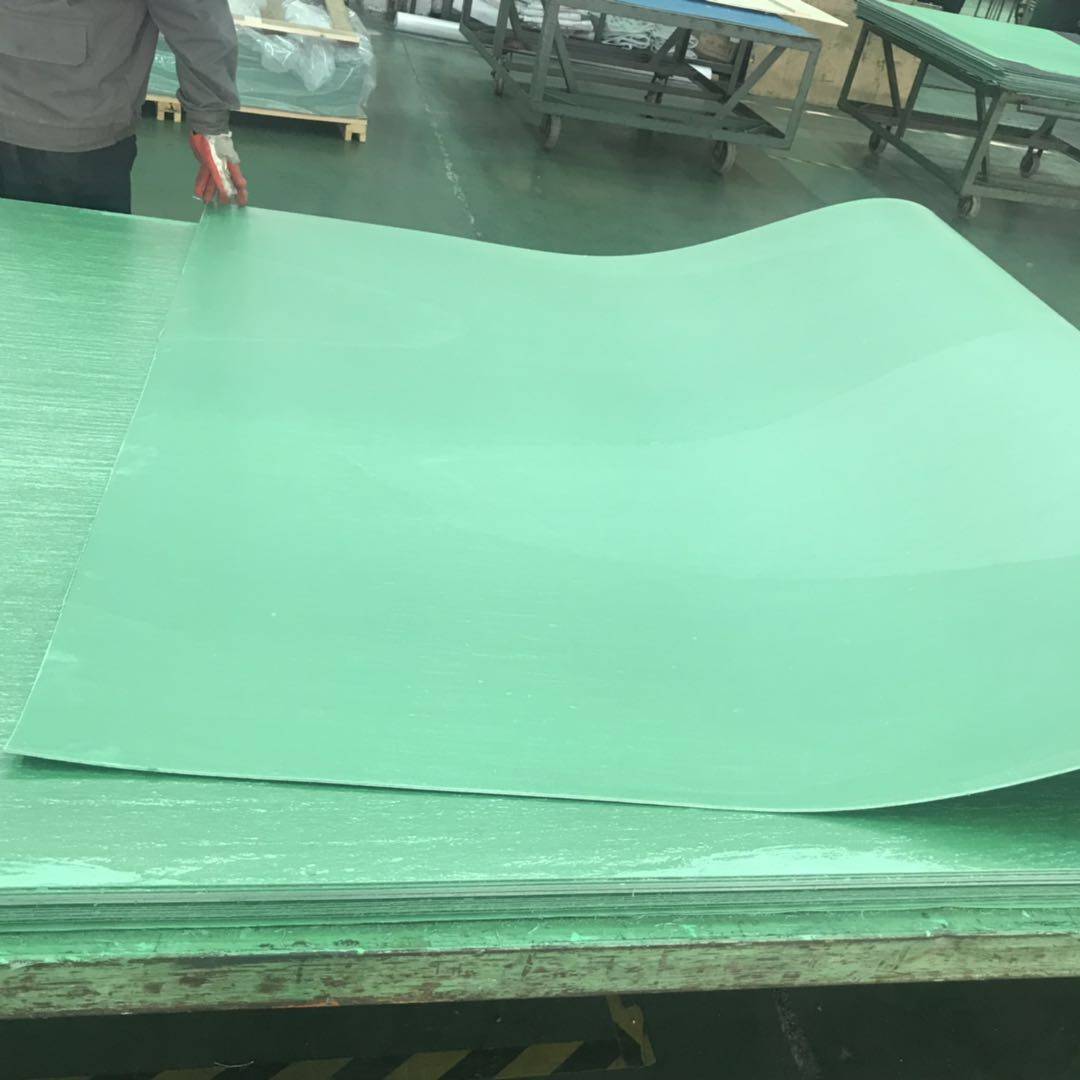

Rules

Sheets: length ≤1150mm,width ≤1150mm, thickness 0.5 to 2.0mm

Special specifications can be agreed with the customer

Physical performance

|

Test conditions |

Pilot project |

Standard |

|

100°C×1h 。 |

The horizontal stretch strength Mpa≥ |

2.0。 |

|

100°C×1h 。 |

Dense g/cm3 |

1.0±0.1 。 |

|

100°C×1h 。 |

The rate of contraction % |

40±7 。 |

| Rebound rate % % |

6。 |

|

|

550°C×1h 。 |

Burn loss % % |

35。 |

|

100°C×22h 。 |

Creep relaxation rate % %≤ |

30。 |

|

Distilled water. |

The thickness change rate %≤ |

15。 |

| Weight change rate %≤ |

45。 |

|

|

Water : glycol is 1:1 100°C×5h 。 |

The thickness change rate %≤ |

15。 |

| Weight change rate %≤ |

60。 |

|

|

ASTM FUEL B。 |

The thickness change rate %≤ |

10。 |

| Weight change rate %≤ |

45。 |

|

|

IRM 903 s standard oil |

The thickness change rate %≤ |

15。 |

| Weight change rate %≤ |

50。 |

|

|

Heat-resistant aging |

The rate of contraction % |

30±7 。 |

| Rebound rate % % |

30。 |

|

| The thickness change rate %≤ |

0±5 。 |

|

| Weight change rate %≤ |

0±3 。 |

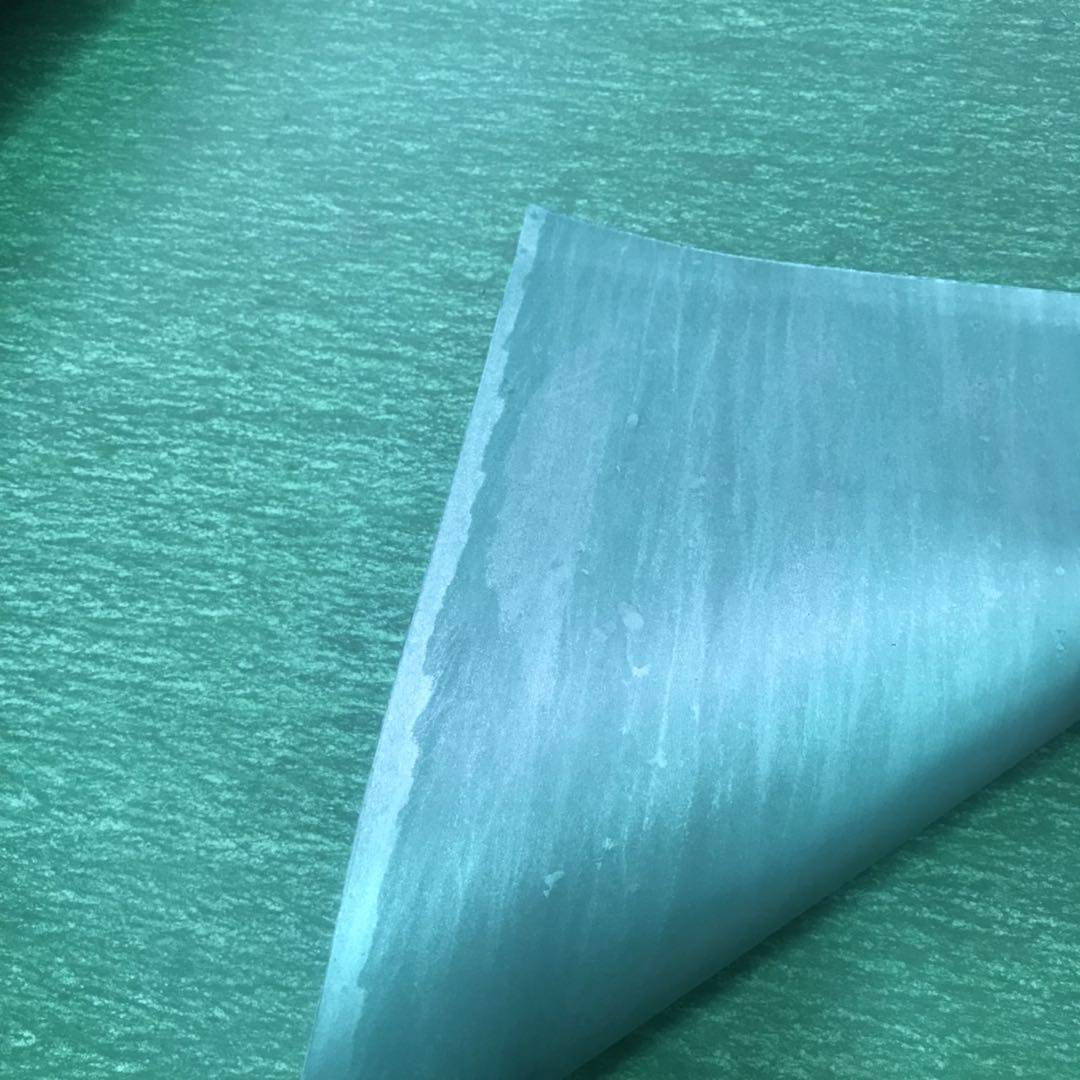

Product detail pictures:

Related Product Guide:

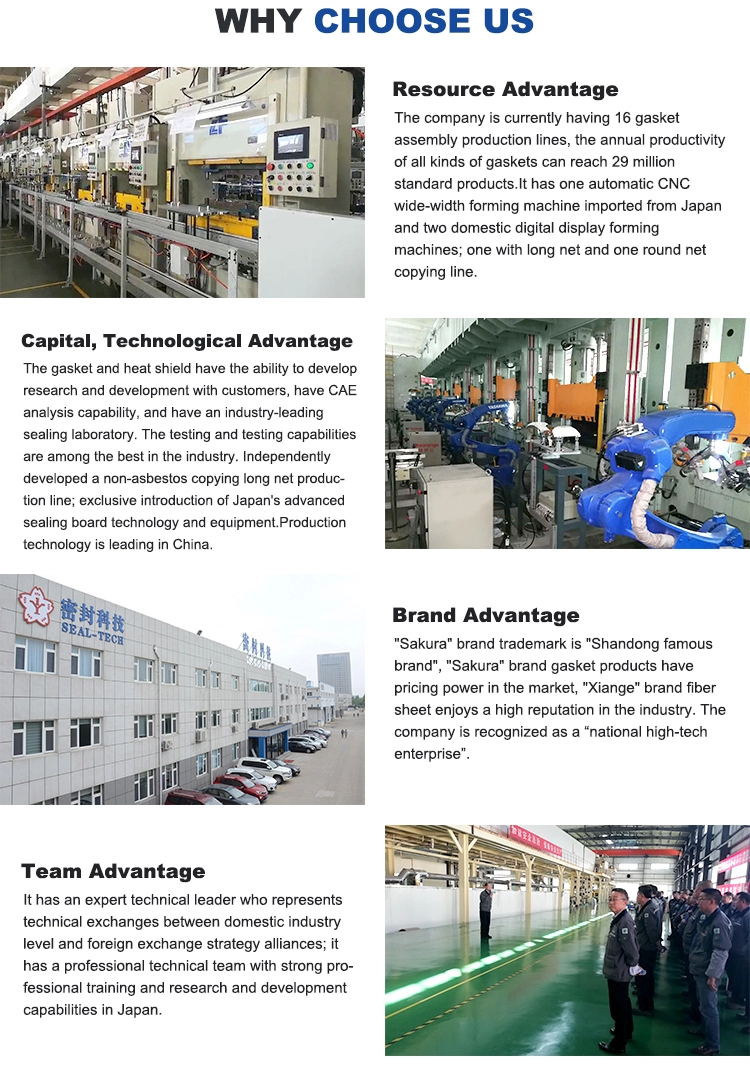

We have been commitment to supply the competitive price ,excellent products and solutions high-quality, at the same time as fast delivery for Discount wholesale Gasket Material For Sealing - FBYS411 fiber-reinforced graphite graphite scribe plate – Ishikawa, The product will supply to all over the world, such as: Moscow, Madras, Irish, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We now have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!